Milling Tools

-

ER Collet Adaptors For Rotary Milling Tables With Fixing T Nuts

ER collet adapters are used to expand the range of tool sizes that can be held by a machine tool or spindle that uses ER collets. By using ER collet adapters, machinists can utilize a wider range of cutting tools without needing separate dedicated tool holders for each collet size, thereby optimizing tooling flexibility, reducing costs, and streamlining setup and changeover times in manufacturing processes. Introduction: ER collet adaptors are precision tool holders used to secure cutting tools in rotary milling tables. They provide a robust and versatile solution for various machining tasks, ensuring high accuracy and repeatability. Design and Construction: Made from high-quality, hardened steel for durability and long-lasting performance. Precision ground to ensure a perfect fit and maximum concentricity. Available in various sizes to accommodate different tool shanks. Compatibility: Designed to fit standard rotary milling tables. Compatible with a wide range of ER collet sizes (e.g., ER11, ER16, ER20) Suitable for use with CNC machines, lathes, and manual milling machines. Clamping Range: ER collets offer a wide clamping range, typically from 1mm to 34mm, depending on the collet size. Provides a secure grip on the tool, minimizing vibration and runout during machining. Advantages: High precision: Ensures accurate tool positioning and stable machining operations. Versatility: Can hold various types of tools, including end mills, drill bits, and taps. Ease of use: Simple to install and change tools quickly, reducing downtime. Improved productivity: Enhances machining efficiency by maintaining tool stability and reducing tool wear. By following these points, users can understand the key features and benefits of ER collet adaptors for rotary milling tables, ensuring they select the right adaptor for their specific machining needs.

$35.50 $32.50

-

Steel Dividing Indexing Plates for Rotary Tables

How it's works: When mounted onto a rotary table, which is a precision workholding device that allows for precise positioning of workpieces, the dividing plate helps in accurately dividing the rotation of the table into equal parts. This division is crucial for tasks like cutting gears, splines, or other components that require precise angular spacing or indexing. Premium Quality Construction: Constructed from high-grade tool steel, ensuring durability and longevity for extended usage. Precision Indexing: Engineered for precise division and indexing, allowing for accurate positioning of workpieces during machining operations. Smooth Rotation: Facilitates smooth rotation on rotary tables, enabling seamless transitions between indexing positions. Versatile Compatibility: Compatible with a wide range of rotary tables, ensuring versatility and adaptability for various machining setups. Enhanced Machining Accuracy: Enables users to achieve fine increments and accurate divisions, enhancing overall machining precision. Easy Installation: Designed for hassle-free installation, allowing users to quickly integrate the indexing plates into their rotary table setups. Reliable Performance: Offers reliable performance under demanding machining conditions, ensuring consistent results with each use. Professional Grade: Ideal for both professional machinists and hobbyists alike, providing professional-grade quality for diverse machining projects. Tools Specification: Dividing Plates Set for HV4 /HV6 Rotary Table: Set Includes: 3 x Indexing Dividing Plate and accessories. Diameter of the Plates is 100 mm. Centre Hole of the Plate is 21 mm. Thickness 7 mm Plate 1 – 15, 16, 17, 18, 19, 20 Plate 2 – 21, 23, 27, 29, 31, 33 Plate 3 – 37, 39, 41, 43, 47, 49 Dividing Plates Set for HV8 /HV10/ HV12/ HV14 Rotary Table: Set Includes: 2 x Indexing Dividing Plate and accessories. Diameter of the plate is 7" and its thickness is 0.47 " Inches (12 mm) approx. All required accessories are included as photograph. No manual is included, please note. Plate A - 28, 32, 37, 39, 43, 46, 49, 53, 59 Plate B - 63, 69, 73, 79, 83, 89, 93, 99 {Internal reference: HM}

$45.50 - $129.99

-

Tool Steel's 65 mm Back Plate for mounting 50 mm Chucks on watchmaker, 2.75" Inch Rotary Tables

Use of product- Back plates serve as mounting surfaces for workpieces or fixtures. They facilitate the secure attachment of the workpiece or fixture to the rotary table, enabling precise machining operations such as milling, drilling, or grinding. Additionally, back plates may incorporate features such as T-slots or mounting holes to accommodate different types of workpieces and tooling setups, enhancing versatility and accuracy in machining processes. Enhance the versatility and functionality of your rotary table with our precision back plate. Crafted from high-quality [Material], this back plate ensures reliable performance and durability for all your machining needs. Features: Robust Construction: Engineered from sturdy tool steel, our back plate is built to withstand heavy-duty machining operations, providing stable support for your workpieces. Precision Machining: Designed with meticulous attention to detail, our back plate offers precise alignment and compatibility with your rotary table, ensuring accurate machining results. Universal Compatibility: Compatible with a wide range of rotary tables, our back plate is a versatile addition to your workshop, catering to various machining projects. Easy Installation: Installing our back plate is quick and straightforward, allowing you to attach it to your rotary table effortlessly for immediate use. Secure Mounting: Equipped with sturdy mounting holes, our back plate ensures a secure and stable connection to your rotary table, minimizing vibrations during machining. Smooth Surface Finish: Finished with a smooth surface, our back plate provides an ideal mounting surface for your workpieces, reducing friction and enhancing machining precision. Size Options: 65 mm diameter back plate in M12 x 1 and M14 x 1 thread. Package Includes: 1 x Precision Back Plate for Rotary Table 3 x Tee Nuts Bolts Upgrade your machining capabilities with our precision back plate for rotary tables. Order now and experience enhanced accuracy and efficiency in your workshop!

$12.95 $11.95

-

Soft Machinable Blank Arbor

A Soft Machinable Blank Arbor is a cylindrical tool or component used in machining processes, particularly in the manufacturing and tooling industry. It serves as a blank canvas for creating custom arbors tailored to specific machining needs Soft blank arbors are used in machining for creating custom tooling, fixtures, and precise components with tailored configurations, enabling versatile and accurate machining operations.. Here's a detailed description: Material: Typically made from soft machinable materials alloy tool Steel. These materials are chosen for their ease of machining and shaping. Shape: The arbor is cylindrical in shape, with precise dimensions to fit into machining equipment such as lathes, milling machines, or drill presses. It may have various diameters and lengths depending on the intended application. Customization: Unlike pre-made arbors, the soft machinable blank arbor allows for customization according to specific requirements. Machinists can shape, drill, tap, and modify the blank arbor to create unique configurations suited to different machining tasks. Versatility: Soft machinable blank arbors offer versatility in their usage. They can be used for holding and securing workpieces, tooling, or other accessories during machining operations. Applications: Soft machinable blank arbors find applications in various industries such as automotive, aerospace, manufacturing, and prototyping. They are used in tasks ranging from simple drilling and milling operations to complex machining projects requiring custom fixtures and tooling. Overall, the soft machinable blank arbor is a versatile and customizable tool essential for machinists and manufacturers seeking precision and flexibility in their machining processes.

$8.99 - $26.50

-

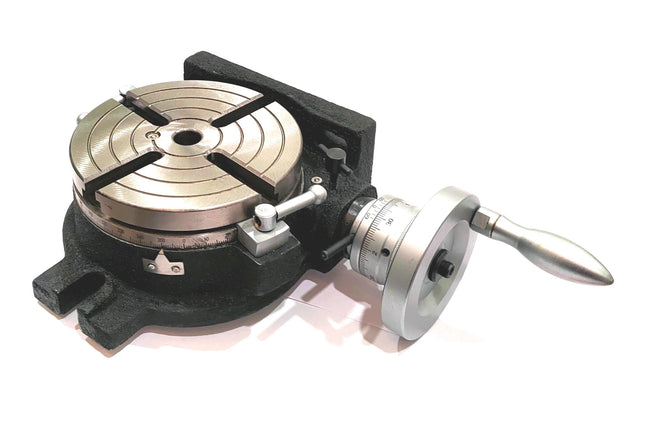

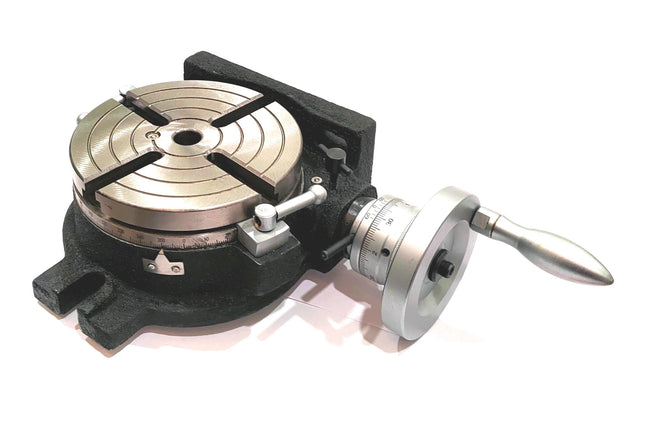

HV6-MT2 Center Bore Rotary Table 6" (150 mm)

Use of Product- A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. Introducing the HV6 Rotary Table, available in both 3-slot and 4-slot configurations. Expertly crafted from seasoned casting, this rotary table features a durable powder-coated wrinkled finish, ensuring long-lasting performance and a professional appearance. Key Features: Gear Ratio: 90:1 gear ratio for efficient table movement, with each handle rotation shifting the table by 4 degrees, enabling precise control. Center Bore: Equipped with a Center Bore MT-2 and a 16 mm T-slot, ensuring seamless compatibility and secure clamping. Versatile Clamping: Can be clamped both vertically and horizontally to accommodate diverse workpiece orientations. Dimensions: The horizontal height is approximately 80mm from the base to the top surface of the chuck, ensuring stability and ease of use. In the vertical position, the center height is 105mm, providing ample clearance for machining operations. Graduations: The table is graduated 360 degrees around its circumference, with a resettable dial and a handwheel graduated in seconds for precise angular adjustments. Lubrication: Equipped with two oiling points for direct lubrication, enhancing the rotary table's longevity and performance. Comprehensive Solutions: Our store offers a range of compatible accessories, including dividing plates, tailstocks, chucks, and clamp kit sets, for a complete machining solution. This HV6 Rotary Table is designed to meet the demands of precision machining, making it an essential tool for any workshop.

$175.50 - $225.50

-

Horizontal Vertical 4" Inch II 100 mm - MT2 Center Bore Tilting Rotary Milling Tables

Precision Engineering: Crafted with meticulous attention to detail, our HV4-MT2 Center Bore Rotary Table ensures superior accuracy and performance in your machining operations. Robust Construction: Built with quality materials, this rotary table boasts a sturdy and durable design, providing long-lasting reliability in your workshop. MT2 Center Bore: Features a reliable MT2 center bore, offering secure mounting and precise alignment for your workpieces. Versatile Compatibility: Compatible with a wide range of machining tasks, including milling, drilling, cutting threads, and more, making it a versatile addition to your workshop. Ample Space: With its HV4 size, this rotary table provides ample space for accommodating various workpieces, allowing you to tackle a variety of projects with ease. Easy to Use: Designed for user convenience, this rotary table is easy to set up and operate, ensuring a smooth and efficient workflow in your machining tasks. Professional Grade: Whether you're a professional machinist or a hobbyist, our HV4-MT2 Center Bore Rotary Table offers professional-grade performance and reliability for all your machining needs. Essential Tool: A must-have tool for any workshop, this rotary table enhances your machining capabilities and helps you achieve precision and accuracy in your projects. Satisfaction Guaranteed: Backed by our commitment to quality and customer satisfaction, our HV4-MT2 Center Bore Rotary Table comes with a satisfaction guarantee, ensuring your peace of mind with every purchase. Upgrade Your Workshop: Elevate your workshop with the superior performance and versatility of our HV4-MT2 Center Bore Rotary Table, the perfect addition to any machining setup.

$134.50 - $134.90

-

Horizontal Vertical 4" Inch II 100 mm Rotary Milling Tables

4" HV Milling Rotary Table available in Regular and Tilting Table Complete Accessories for 4" Tilting Rotary Table — Only Here! We offer everything you need for your 4-inch tilting rotary table — including the world's first-ever available dividing plate exclusively with us! Vertical & Horizontal Design Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. Chamfered Sides Our 4-inch rotary table features a chamfered design, ensuring smooth edges for safer handling and easy alignment. The chamfered edges also enhance the aesthetic appeal while reducing the risk of edge damage during use. Wrinkle or Stoving Paint The rotary table is equipped with an oil nipple for easy lubrication, ensuring smooth and long-lasting rotation. It also features a locking screw to securely hold the table in position during machining for precise results. Oil Nipple & Locking Screw All working surfaces of the rotary table are precision ground to ensure high accuracy and smooth operation. This enhances alignment, reduces runout, and delivers consistent performance in precision machining tasks. Cup Grinded The rotary table comes with a cap ground finish, providing a smooth, flat surface that enhances accuracy during setup. This precision finish ensures better contact with fixtures and improved machining consistency. Gun Metal Gear The rotary table features a gunmetal gear, known for its excellent wear resistance and smooth operation. This ensures reliable performance, reduced friction, and a longer lifespan, even under continuous use. 4" Vertical & Horizontal Tilting Rotary Table The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from casting with high quality. They are are very popular on the market for their superior performance, excellent design and reasonable cost. Remarkable Quality Excellent Precision Multiple Application Vertical & Horizontal Design Specifications Table Diameter: 4" Table is graduated 360 Degrees. Worm Gear Ratio -1:36 Center Height in horizontal position when lay flat : 2-3/4" (70 mm approx) Center Height in vertical position: 3" Inch approx (77 mm) Base Dimensions : 142 x 128 mm 2 Opposite counter drills of 9.5 mm diameter are located at a PCD of 102 mm approx for mounting. 4" Vertical & Horizontal Regular Rotary Table The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from casting with high quality. They are are very popular on the market for their superior performance, excellent design and reasonable cost. Remarkable Quality Excellent Precision Multiple Application Vertical & Horizontal Design Specifications Table Diameter: 4" Table is graduated 360 Degrees. Worm Gear Ratio -1:36 Height when laid horizontally 2-5/16" Inches ( 58 mm ) Center Height in vertical position: 2-1/8" (53.5 mm approx) Base Dimensions : 135 mm x 105 mm with 2 x U slots (9.5 mm)

$50.40 - $116.90

-

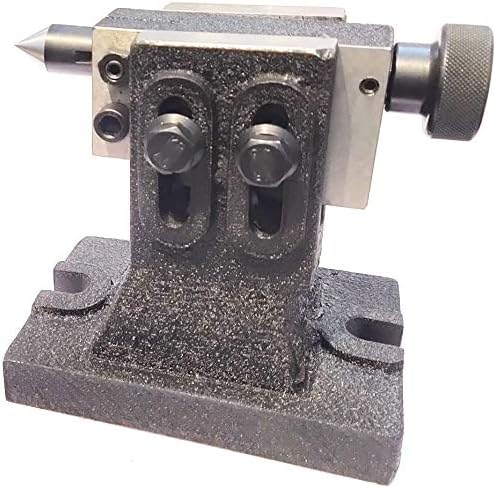

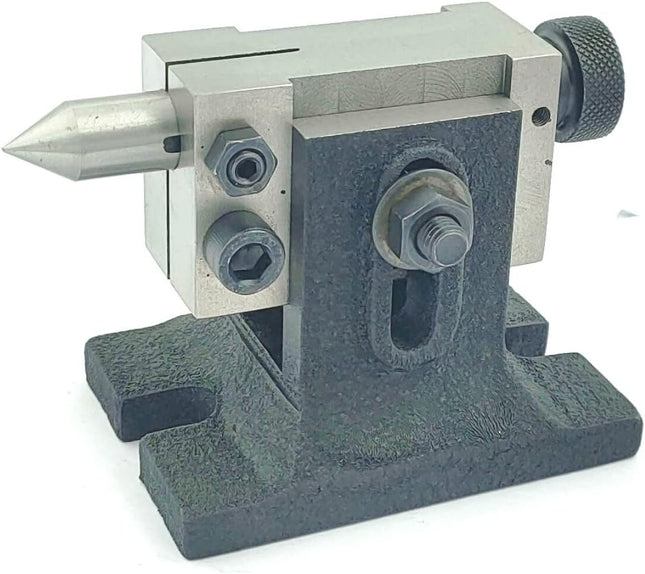

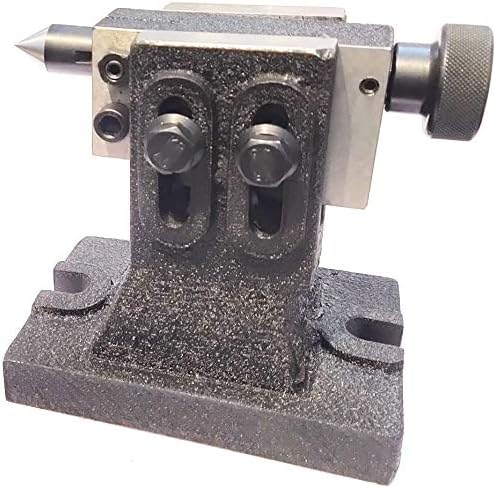

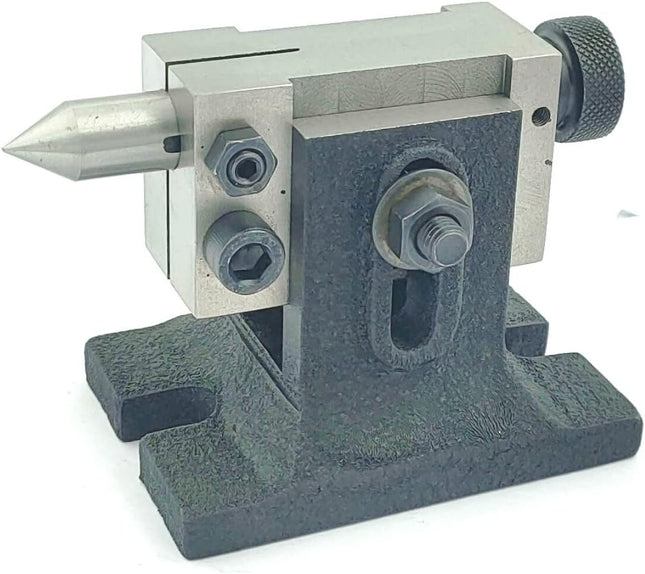

Heavy Duty Adjustable Tailstocks for Rotary Tables (Hardened & Precisely Ground Points)

Used For: A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine. It is usually used to apply support to the longitudinal rotary axis of a workpiece being machined. Heavy Duty Construction: Built to last with tool steel, providing stability and support for your machining tasks. Adjustable Height: Easily adjust the height to accommodate different workpieces and machining requirements. Versatile Compatibility: Available in various sizes compatible with 3" / 4" rotary tables as well as HV4/HV5/HV6/HV8 rotary tables, ensuring compatibility with a wide range of setups. Smooth Operation: Ensures smooth and precise performance, enhancing the accuracy of your machining operations. Easy Installation: Designed for hassle-free installation, allowing you to quickly set up and start machining. Enhanced Stability: Provides a solid foundation for your workpieces, minimizing vibration and ensuring consistent results. Wide Application: Suitable for various machining tasks, from milling to drilling, turning, and more. Essential Accessory: A must-have addition to your rotary table setup, enhancing its functionality and versatility for diverse machining projects. Professional Quality: Designed for professional machinists and hobbyists alike, offering reliability and performance you can trust. Available in Different Sizes: Choose the size that best fits your rotary table setup, ensuring a perfect fit and optimal performance. Tailstock HV4/ HV5/ HV6- Minimum Center Height 80 mm & Maximum Center Height is 105. Base Dimension 135 mm x 90 mm/ HV8- Base dimension - 190 x 150mm * Overall casting height - 205mm * Weight - 10kg. Centre Height maximum - 215mm * Centre Height minimum - 130mm * Centre travel - 30mm [Internal Reference: HM}

$53.99 - $134.95

-

Small Watchmaker's Milling Rotary Tables

Use of product- The small watchmaker rotary table is a versatile tool with a multitude of uses. It's indispensable in precision watchmaking, enabling accurate drilling, milling, and engraving for crafting and repairing intricate watch components. Additionally, it's favored by jewelry makers for its ability to shape metals with precision, from setting stones to creating bespoke jewelry pieces. Compact Design: Table Diameter of 2.75 inches (72 mm) and a height of 1.5 inches (39 mm) when laid horizontally, offering a space-efficient solution. Precision Performance: Worm-Gear Ratio of 1:48 ensures precise positioning, with each handle rotation turning the table by 7.5 degrees, ideal for intricate milling tasks. Versatile Utility: Preferred choice among Watchmakers, Jewelry Tools, Model Makers & Hobbyists for its versatility in engraving, drilling, cutting, and shaping small components. Robust Construction: Crafted with high-quality materials and precision machining, guaranteeing durability and reliability for professional workshops and hobbyist setups. Smooth Operation: Equipped with smooth ball bearings and precision gearing, enabling effortless rotation and stable operation for flawless milling results. User-Friendly: Designed with ergonomic handles and intuitive controls for ease of use, reducing operator fatigue during extended milling sessions. Trusted Performance: Trusted by professionals and hobbyists alike for consistent precision and reliability, meeting exacting standards for precision milling applications. Available in 2 slots and 4 slots

$62.50 - $62.99