Lathe Parts & Accessories

-

Buyohlic Micro Fine Drill Adaptor Miniature Quill 0-1/8 INCH/ 0-3MM JT0 Keyless Drill Chuck Taper to mount Drill Chuck

Use of product- A micro drill adaptor is used to connect small drill bits to a power tool. It allows you to use very tiny drill bits for delicate and precise drilling tasks, such as in electronics, jewelry making, or detailed woodworking. Versatile Compatibility: This JT0 micro drill chuck is designed to accommodate a wide range of drill sizes, ranging from 0-3MM , offering versatility for various drilling tasks. Secure Grip: The key-type design ensures a secure grip on your micro drills, minimizing slippage and ensuring precise drilling operations. Precision Engineering: Crafted with precision engineering, this drill chuck provides accurate and reliable performance, allowing for consistent drilling results. Durable Construction: Made from high-quality materials, this micro drill chuck is durable and built to withstand the demands of frequent use in workshops and DIY projects. Easy Adjustment: The keyless design allows for easy and convenient adjustment of the chuck to accommodate different drill sizes, enhancing workflow efficiency. Compact Size: With its compact and lightweight design, this micro drill chuck is ideal for use with micro drill adaptors, offering convenience and ease of use in confined spaces. Wide Application: Suitable for various drilling applications, including woodworking, metalworking, electronics, and precision machining, making it a versatile tool for hobbyists and professionals alike. Enhanced Control: Achieve greater control and accuracy in your drilling tasks with this micro drill chuck, ensuring precise hole placements and clean drilling results. Quick Installation: Easy to install and remove, this drill chuck allows for quick setup and hassle-free interchangeability, saving you time and effort during project work. Value Pack: Invest in this micro drill chuck to enhance the capabilities of your drill adaptor, providing excellent value for hobbyists, craftsmen, and DIY enthusiasts.

$38.99 - $134.99

-

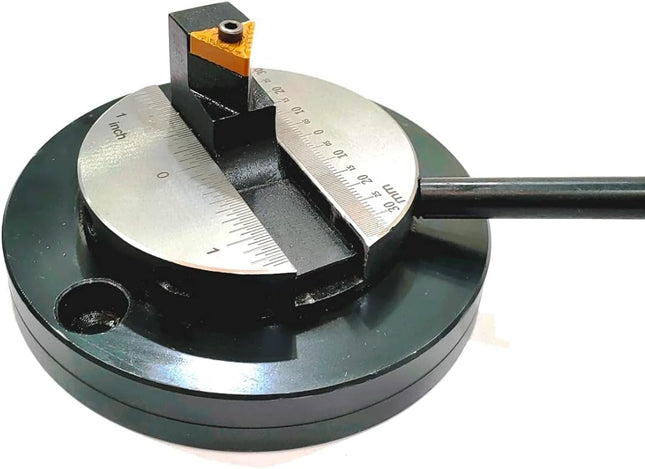

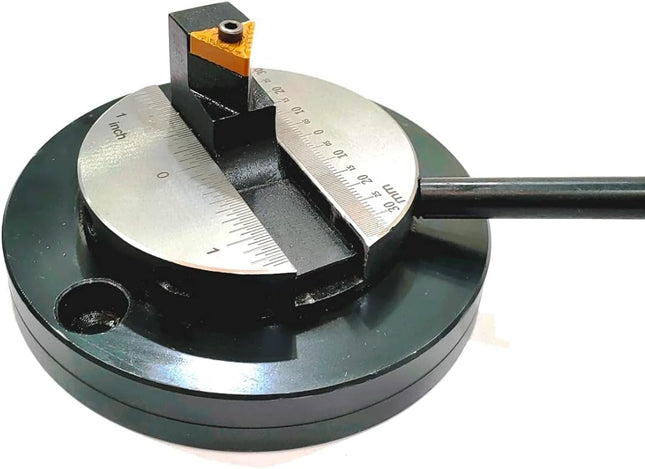

Buyohlic Lathe's Round Base Ball Turning Attachment with Size Scale

Use of product- A ball turning tool is used in machining to create round or spherical shapes on metal or other materials. It's commonly used for making parts like ball bearings, spherical valves, or curved ends of rods with precise dimensions and smooth surfaces. Product Name: Lathe's Ball Turning Attachment with Size Scale Base Type: Round base Bit Options: Available in double bit Available in single bit Adjustable Head: Head can be adjusted to accommodate different ball sizes, providing flexibility for various projects. Maximum Concave Ball Diameter: Maximum possible concave ball diameter is 42 mm Potential for larger diameters depending on the user's skills and expertise. Key Features: Size Scale: Integrated size scale for precise adjustments and accurate ball turning. Versatile Bit Options: Choice between single bit and double bit attachments, catering to different user preferences and project requirements. Adjustability: Head adjusts easily to produce different ball sizes, enhancing the tool's versatility. Construction: Made from high-quality materials ensuring durability and longevity. Precision-engineered to withstand the demands of ball turning operations. Applications: Ideal for turning concave and convex balls on a lathe. Suitable for both hobbyists and professional machinists. Usability: User-friendly design with straightforward setup and operation. Smooth and easy adjustments for precise control during ball turning. Performance: Capable of producing accurate and consistent ball shapes. Enhanced flexibility allows for the creation of balls larger than the specified maximum diameter, based on user expertise. Dimensions: Compact Design: Optimized to fit a wide range of lathes, making efficient use of space and ensuring ease of handling. Additional Features: Integrated Size Scale: Provides clear and accurate measurements for precise ball turning. Robust Construction: Ensures stability and reliability during use. Skill Enhancement: Offers potential for larger diameter balls with increased user skill and experience. Ease of Use: Simple to set up and adjust, making it accessible for users of all skill levels. Designed to provide smooth operation and precise control, enhancing the overall turning experience. This Lathe's Ball Turning Attachment with Size Scale is an essential accessory for any lathe, providing the capability to turn precise and consistent balls with ease and accuracy.

$49.50 - $54.90

-

5C Horizontal-Vertical Angle Collet Holding Fixture

Collet fixtures typically consist of a collet, which is a specialized type of chuck or clamp that can hold various sizes of cylindrical objects, and a mechanism for tightening or releasing the collet to secure or remove the workpiece or tool. They are often used in applications where high precision and repeatability are essential, such as in the production of small or intricate parts for industries like aerospace, automotive, and medical devices. Premium Quality: Precision-engineered 5C collet fixture crafted for durability and reliability in machining operations. Versatile Compatibility: Designed to accommodate 5C collets, ensuring a secure grip on various workpiece sizes. Easy Setup: Compact and ergonomic design facilitates quick and hassle-free installation, saving time and effort. Adjustable Features: Intuitive controls and adjustable settings allow for easy customization to meet specific machining needs. Accurate Positioning: Offers precise indexing capabilities for accurate alignment of workpieces during drilling, milling, grinding, and more. Enhanced Efficiency: Say goodbye to guesswork with this fixture's ability to streamline machining processes, boosting productivity in your workshop. Trusted Performance: Trusted by machinists, engineers, and craftsmen for consistent performance and reliability, making it a valuable addition to any workshop. Tools Specifications:- For any standard 5C collet Base Size (vertical): 5 x 3-5/8" Lever movement to open or close collet. Base Size (horizontal): 5 x 4"

$99.00 $82.50

-

1-1/2" Inch Head Fly Cutter with MT2 Shank (M10 x 1.5 Drawbar) & HSS M2 5/16" Sq x 3" Inch Tool Bit

Dimensions of the Fly Cutter Precision Fly Cutter – The Ultimate Tool for Flawless Surface Finishing A fly cutter is a versatile milling tool designed to produce exceptionally flat surfaces with fine finishes, ideal for both roughing and finishing operations on materials like steel, cast iron, and aluminum. Particularly effective on low-horsepower spindles, it offers a cost-effective alternative to standard milling cutters. Engineered with precision in mind, it's the tool of choice for watchmakers, jewelers, and miniature engineers who demand ultra-fine machining results. Whether in a professional workshop or a precision hobby setting, this fly cutter delivers reliable performance and superior surface quality. Material of Fly Cutter The fly cutter is typically equipped with a High-Speed Steel (HSS) tool bit, known for its excellent hardness, heat resistance, and durability. HSS allows the cutter to maintain a sharp edge even at high cutting speeds, making it ideal for machining a wide range of materials. Tool steel construction ensures strength and wear resistance, enabling precise, smooth cuts and extended tool life—perfect for both roughing and fine finishing work. About The Brand Buyohlic is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Buyohlic is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Buyohlic's products are sold in more than 200 countries.

$24.99 $22.50

-

Tool Steel 60 Degree Dead Center Centre- lathe Drill, Mill, Grinder Tools

A dead center lathe tool is used to support and align workpieces in a lathe by providing a fixed point in the tailstock, ensuring the workpiece is stable and accurately aligned with the spindle axis. This support is crucial for maintaining rotational symmetry, reducing deflection and vibration, and achieving precise machining with a high-quality surface finish. By minimizing movement and ensuring proper alignment, the dead center plays a key role in producing concentric and uniformly cut parts. Precision Machining: Elevate your lathe operations with our high-quality lathe dead centers, available in MT1, MT2, MT3, and MT4 shanks to suit your specific needs. Versatile Shank Options: Choose from a range of shank sizes, including MT1, MT2, MT3, and MT4, ensuring compatibility with a variety of lathe setups. Robust Construction: Crafted from durable materials, our lathe dead centers are built to withstand the rigors of machining, ensuring long-lasting performance and reliability. Optimal Support: Designed to provide optimal support and alignment for your workpiece, our dead centers help minimize vibration and improve machining accuracy. Smooth Rotation: Experience smooth and consistent rotation with our precision-engineered lathe dead centers, facilitating precise turning and machining operations. Easy Installation: Featuring a hassle-free installation process, our lathe dead centers can be quickly and securely mounted on your lathe, allowing you to get to work with minimal setup time. Wide Application: Whether you're working on woodworking projects, metalworking tasks, or other machining applications, our lathe dead centers offer versatility and performance across a range of materials and projects. Upgrade your lathe setup with our precision lathe dead centers, available in MT1, MT2, MT3, and MT4 shanks, and experience enhanced machining accuracy and efficiency. {Internal Reference; HM}

$9.90 - $44.99

-

Lathe Tailstock Threading Die Holder- 3/8" Straight Shank

Use of product- Upgrade your lathe threading capabilities with the Precision Straight Lathe Die Holder, an essential tool for any machinist's workshop. Designed for durability and precision, this die holder facilitates smooth and accurate thread cutting operations on your lathe, ensuring professional results with every use. Key Features: Robust Construction: Crafted from high-quality materials, including sturdy steel components, this straight lathe die holder is built to withstand the rigors of industrial machining. Its rugged construction ensures long-lasting durability and reliability, even under heavy use. Secure Grip: Equipped with precision-engineered jaws, this die holder provides a secure grip on standard-size dies, preventing slippage during threading operations. The tight grip ensures consistent performance and precise thread cutting results on various workpiece materials. Straight Shank Design: Featuring a straight shank design, this die holder offers increased stability and rigidity during threading operations, minimizing vibration and ensuring smooth, accurate cuts. The straight shank design also allows for easy mounting and alignment on your lathe. Versatile Compatibility: Compatible with a wide range of lathe models and sizes, this die holder is suitable for both professional and hobbyist machinists. Whether you're working on large industrial projects or small-scale DIY tasks, this versatile tool delivers the performance and precision you need. Easy to Use: Designed for user-friendly operation, this straight lathe die holder is easy to install and adjust on your lathe, allowing for quick and efficient setup. Its intuitive design makes it suitable for machinists of all skill levels, from beginners to experienced professionals. Wide Application: Ideal for cutting external threads on cylindrical workpieces, this die holder is perfect for a variety of applications, including automotive repairs, plumbing projects, and metalworking tasks. From creating custom threads to repairing damaged threads, this versatile tool ensures exceptional results every time. Enhance your lathe threading capabilities with the Precision Straight Lathe Die Holder. Whether you're working on professional machining projects or DIY repairs, this essential tool provides the durability, precision, and versatility you need to achieve outstanding thread cutting results. Invest in quality craftsmanship and elevate your machining capabilities today! {Internal Reference:- HM}

$26.90 - $32.50

-

High Grade Caste Iron Straight Style Lathe Dog

A high-grade cast iron bent-style lathe dog is a device used in metalworking on a lathe machine. Its primary purpose is to hold a workpiece securely in place while it's being machined. The lathe dog typically consists of two parts: a body that clamps onto the workpiece, and a tail that fits into a slot on the lathe's driving plate or faceplate. This arrangement allows the workpiece to rotate along with the lathe spindle, enabling precise cutting and shaping operations. The lathe dog helps prevent the workpiece from rotating independently, ensuring accuracy and consistency in machining processes.. Here's a detailed description: Material: Constructed from high-grade cast iron, ensuring durability, strength, and resistance to wear and tear even under heavy usage. Design: The bent-style design typically features a curved or angled shape, allowing it to securely grip the workpiece while minimizing interference with the cutting tool or lathe components. Jaws: Equipped with strong, precision-machined jaws that provide a firm grip on the workpiece without causing damage. The jaws may have serrated surfaces to enhance grip and prevent slippage during machining. Adjustability: Some models may feature adjustable jaws or clamping mechanisms to accommodate various sizes of workpieces, offering versatility in application. Accuracy: Designed with precision tolerances to ensure accurate centering and alignment of the workpiece, resulting in precise machining operations and high-quality finished products. Compatibility: Designed to fit specific lathe spindle sizes and configurations, ensuring compatibility with a wide range of lathes and machining setups. Surface Finish: Finished with smooth surfaces and edges to minimize friction and wear on the workpiece while ensuring ease of installation and removal. Heat Resistance: Capable of withstanding high temperatures generated during machining processes without deformation or loss of gripping effectiveness. Size Range: Available in various sizes to accommodate different workpiece diameters and configurations, providing flexibility for diverse machining requirements. Safety Features: May include features such as safety stops or guards to prevent accidental contact with rotating parts during operation, ensuring operator safety. Overall, a high-grade cast iron bent-style lathe dog is an essential tool for machinists and metalworkers, offering reliable performance, precision, and durability in a wide range of turning applications. Internal ref.BA

$12.50 - $53.55

-

Lathe Tailstock Alignment Mendral Test Bar

A test bar is used to evaluate the mechanical properties and quality of materials. It helps determine characteristics such as strength, durability, and performance, ensuring that the materials meet specific standards and are suitable for their intended applications. Test bars are essential in industries like manufacturing, construction, and metallurgy for quality control, research, and development, as well as for calibrating testing equipment. Introducing the Lathe Tailstock Alignment Mendral Test Bar, your go-to solution for precision engineering on the lathe. Crafted with meticulous attention to detail, this test bar is designed to ensure optimal alignment of your lathe tailstock, guaranteeing unparalleled accuracy in your machining operations. Key Features: Superior Precision: Engineered from high-grade steel, this test bar delivers exceptional accuracy, allowing you to achieve precise alignment of your lathe tailstock with ease. Durable Construction: Built to withstand the rigors of daily use in the workshop, the Mendral Test Bar boasts durability and reliability, ensuring long-lasting performance. Easy Alignment Checks: With its user-friendly design, performing alignment checks is a breeze. Simply insert the test bar into your lathe chuck or collet and follow the straightforward instructions for precise alignment adjustments. Versatile Compatibility: Compatible with a wide range of lathe setups, this test bar seamlessly integrates into your existing equipment, catering to the needs of both professionals and hobbyists alike. Elevate Your Machining Experience: Whether you're a seasoned machinist striving for perfection or a hobbyist enthusiast seeking to enhance your skills, the Mendral Test Bar empowers you to take your machining endeavors to new heights of precision and excellence. Invest in the Lathe Tailstock Alignment Mendral Test Bar today and experience the difference it makes in optimizing your lathe performance. {Internal Reference: HM}

$9.00 - $89.99

-

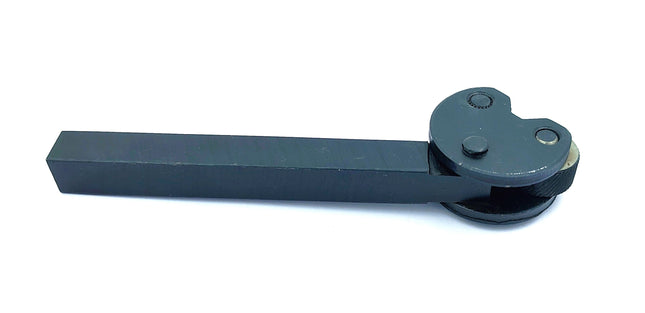

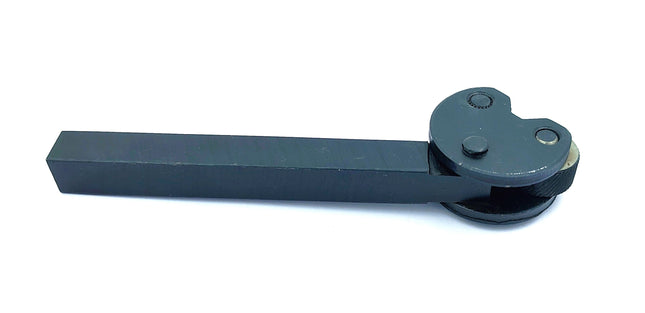

Buyohlic Pivot Head Knurling Tool Medium Diamond Metric Pitches Pattern 1/2" Sq. Shank

2 Wheel Pivot Head Diamond Metric Pattern 1/2" Sq. Shank Medium Size of Pivot Head The knurling tool has a 1/2" square shank, making it ideal for small to medium-sized lathes. It features hardened alloy steel knurls, ensuring durability and precision for knurling operations. Crafted from high-Quality Tool Steel This Pivot Head is manufactured using premium high-quality tool steel, known for its exceptional strength, wear resistance, and durability. The tool steel composition ensures: Superior Hardness – Maintains sharp knurling edges for long-lasting performance. High Wear Resistance – Withstands repeated use without deformation or excessive wear. Excellent Toughness – Resists chipping and breakage, even under high-pressure applications. Corrosion Resistance – Designed to endure harsh working conditions, ensuring longevity. Pivot Head's Feature This knurling tool has a 1mm pitch medium knurl, meaning the spacing between the knurling ridges is 1mm, creating a balanced texture. It comes with a 1/2" square shank, suitable for small to medium-sized lathes. The tool features both left-hand (LH) and right-hand (RH) diagonal line knurls, which intersect to form a diamond pattern for improved grip and aesthetic finish. Use of Pivot Head The pivot head in a knurling tool allows the knurling wheels to self-align with the workpiece, ensuring even pressure distribution. This helps to:Reduce tool and workpiece stress by preventing excessive force on one side.Improve knurling accuracy by maintaining uniform contact.Extend tool life by minimizing uneven wear on the knurling wheels.Enhance surface finish by producing a consistent knurl pattern.It is especially useful for knurling on small to medium-sized lathes, where maintaining precision is critical. Precision Knurling Tool with Pivot Head – Durable, Accurate & Ideal for Small to Medium Lathes This knurling tool features a 1/2" square shank, ideal for small to medium-sized lathes. It has hardened alloy steel knurls for durability and precision. The pivot head, made from high-quality tool steel, offers superior hardness, wear resistance, toughness, and corrosion resistance. With a 1mm pitch, it creates a diamond knurl pattern using LH & RH diagonal knurls. The pivot head self-aligns, reducing stress, improving accuracy, and ensuring a consistent finish. Durable Construction – Made from high-quality tool steel for superior strength and wear resistance. Precision Knurling – 1mm pitch medium knurl with LH & RH diagonal knurls for a sharp diamond pattern. Self-Aligning Pivot Head – Ensures even pressure distribution for accurate and consistent knurling. Versatile Compatibility – 1/2" square shank, ideal for small to medium-sized lathes. Extended Tool Life – Resistant to wear, deformation, and corrosion for long-lasting performance. About the BrandBuyohlic is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Buyohlic is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Buyohlic's products are sold in more than 200 countries.

$14.95 $13.50

-

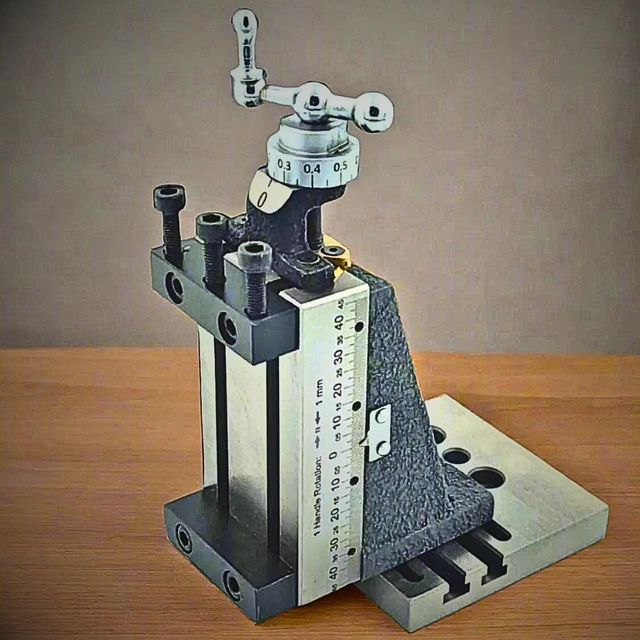

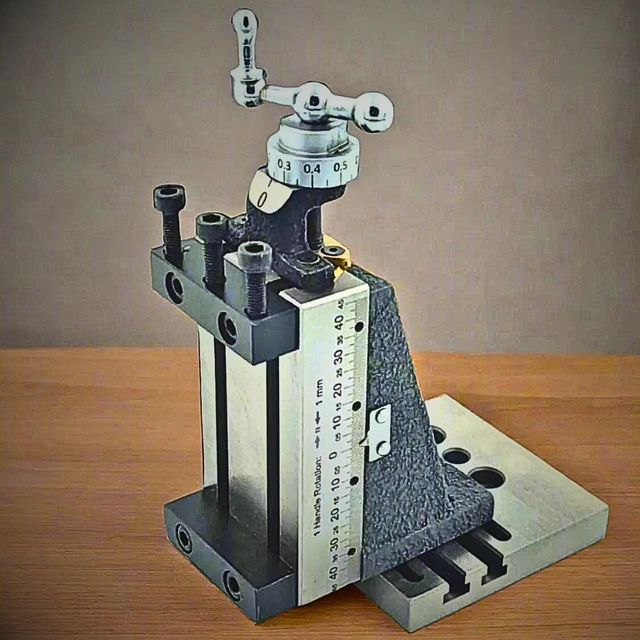

New Model Mini Lathe Milling Vertical Slide Tool Holder, Cast Iron Quick-Change Lathe Tool for Instant Milling, WM180V/WM210V

✅ Material: Made of cast iron, providing strength, durability, and resistance to wear and corrosion. Ensures a long service life for repeated use in various lathe operations. 📐 Specifications: Maximum clamping range: 75mm (2.95"), maximum lifting stroke: 84mm (3.3"), total height: 170mm (6.69"). Each rotation of the tool holder has an accuracy of at least 0.02mm for precise operation. 🛠️ Easy Operation: Dial design allows adjustment of clamping range with high accuracy. Each grid rotates at least 0.02mm, making operation simple and precise. ⚙️ Function & Design: Used to clamp the chuck, tailstock, turning tool, and milling chuck. Compact structure weighing 3kg (6.6lb), vertical sliding for fast clamping, suitable for lathes like WM180V and WM210V. 📦 Package Included: 1 piece of vertical lifting tool holder included.

$89.99

-

CNC Lathe Universal Boring Tool Holder with Interchangeable Sleeves – Precision Boring Bar Holder for CNC & Traditional Lathe Machines

CNC Lathe Boring Tool Holder with Interchangeable Sleeves – Precision Boring Bar Holder for CNC & Traditional Lathe Machines Product Overview: Get more versatility from your lathe setup with this CNC Lathe Boring Tool Holder featuring an interchangeable sleeve system. Designed to work on both CNC and conventional lathes, this innovative holder allows you to use boring bars of different diameters with the same holder — saving time, cost, and tool space. Each unit includes a set of precision-ground ID sleeves, all having the same outer diameter (OD) as the holder bore for perfect interchangeability. The sleeve holes align with the square-head bolts on the main holder to ensure the boring bar locks firmly in place and maintains perfect alignment with the cutting centerline. This smart design ensures maximum rigidity, improved cutting accuracy, and longer tool life — ideal for internal turning, facing, and precision boring applications. ⚙️ Key Features: ✅ Universal Compatibility:Works perfectly with CNC and manual lathe machines for boring operations. ✅ Interchangeable Sleeve System:Use the same holder for different boring bar diameters — no need for multiple holders. ✅ Precision Locking Alignment:Sleeves are drilled to match locking bolt positions, ensuring firm grip and accurate alignment. ✅ True Cutting Center:The boring bar rests directly on the holder base — not the sleeve — to maintain true cutting center and prevent tip displacement. ✅ High Durability & Rigidity:Manufactured from premium alloy steel for superior strength, vibration resistance, and long service life. ✅ Multiple Shank Sizes Available:Choose from different shank size options in the dropdown menu to fit your machine’s tool post or turret. ✅ Cost-Effective Solution:Eliminates the need to purchase multiple boring holders — one holder handles it all. Holder Height (MM) Holder Width (MM) Center Hole (MM) OAL (MM) Nozzle I Sleeves' D (MM) 25 25 25 100 20, 16, 12, 10, 8, 9, 7, 6 20 20 20 90 16, 12, 10, 8, 7, 6 16 16 16 90 12, 10, 8, 7, 6 12 12 16 80 12, 10, 8, 7, 6 10 12 12 70 8,7, 6 📦 Package Includes: 1 × CNC Lathe Boring Tool Holder Set of Interchangeable ID Sleeves (Same OD as Holder Bore) ⚠️ Important Note: The boring bar shown in product images is not included. It is shown for illustration purposes only. 🏭 Applications: Internal Turning Boring & Facing Operations Chamfering & Fine Hole Finishing Precision Machining for CNC & Conventional Lathes 🔑 Search Keywords (for SEO): CNC boring tool holder, interchangeable sleeve boring bar holder, lathe boring tool holder set, precision lathe boring bar holder, universal boring bar tool holder, CNC turning tool holder, boring bar adapter sleeves, lathe tool holder for boring bars, internal turning tool holder, multi-size boring tool holder.

$64.99 - $79.99

-

Morse Taper's Arbor to Mount JT2 Keyless Drill Chuck

Mount Type: Jacobs Taper #2 (JT2) – provides a secure friction-fit connection between the chuck and arbor/spindle. Capacity Range: 1-13mm Material: hardened steel for durability and wear resistance. Type: keyless Usage: Ideal for use in drill presses, milling machines, lathes, or other stationary equipment. Applications: Metalworking Woodworking Precision drilling Industrial and manufacturing tasks Chose from a variety of option of MT2/3 & R8 shanks - all having JT2 mounting tapers to mount the drill chuck along.

$52.99 - $57.90