Chucks for Milling and Turning Operations

Chucks play a critical position in each milling and turning operation. They are used to hold workpieces or cutting tools firmly, enabling machines to operate with accuracy, safety and consistency. Without a proper chuck, even a powerful gadget can't produce precise effects.

In turning operations on a lathe, chucks usually hold round or cylindrical workpieces. Common turning chucks grip the cloth tightly whilst it rotates, allowing for operations that include facing, drilling, uninteresting, and external turning. A sturdy grip prevents slippage, even at better speeds.

In milling operations, chucks feature barely otherwise. Here, they frequently hold cutting tools instead of the workpiece. Milling chucks are designed for low runout and high rigidity, helping gain smooth surface finishes and particular dimensions. This is specifically essential throughout high-speed or precision milling.

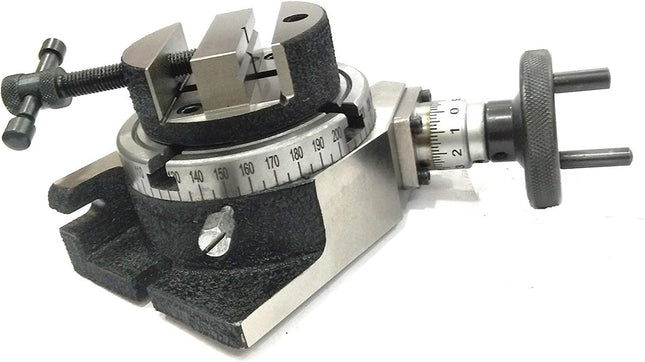

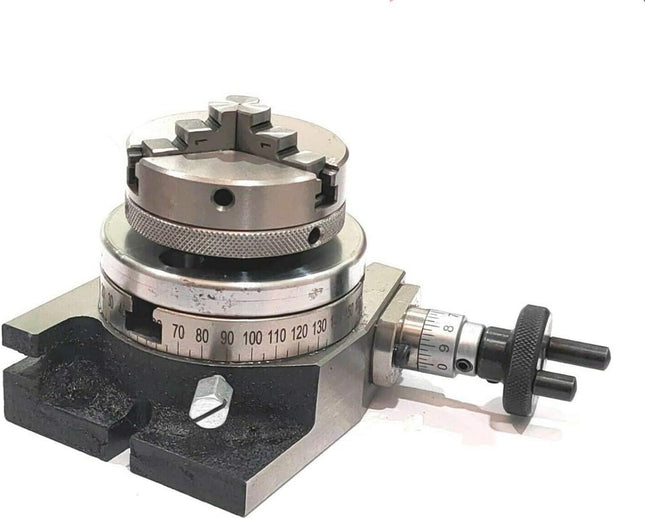

Specialized gadgets like rotary tables with chucks and indexing chucks add flexibility to milling machines. A rotary indexing table allows the workpiece to rotate in controlled steps, making it easier to perform circular cutting, gear cutting, or evenly spaced machining operations. Indexing plates help lock the workpiece at exact angles, improving repeatability and accuracy.

For heavier or automatic methods, power and hydraulic-style chuck systems (used conceptually in milling setups) provide a strong clamping force with minimum guide effort. These structures are preferred in commercial settings in which consistency and productivity are vital.

Overall, chucks improve:

- Machining accuracy

- Workpiece stability

- Surface finish quality

- Operator safety

- Production efficiency

Whether you're walking into a small workshop, a tool room, or a business machining unit, deciding on the proper chuck for milling or turning operations makes a noticeable distinction in results.

At Buyohlic, chucks and associated accessories are selected to support everyday workshop use, precision machining, and dependable overall performance across milling and turning applications.