Products

-

Slotted Slim Angle Plate 150 x 58 x 58 mm-Suitable for Lathes Including Myford & ML7 series Caste Iron

Enhance your machining precision with the Slotted Slim Angle Plate, expertly designed for versatility and durability. Perfectly sized at 150 x 58 x 58 mm, this compact yet robust angle plate is ideal for use with Myford & ML7 series lathes, among other compatible setups. Key Features: Precision Engineering: Crafted for accurate 90° angles, ensuring precise positioning and alignment during machining operations. Durable Construction: Made from high-quality cast iron for exceptional rigidity and long-lasting performance. Slotted Design: Features strategically placed slots to facilitate easy clamping and secure mounting of workpieces. Slim Profile: Compact dimensions and lightweight construction allow for convenient handling and versatility in tight spaces. Wide Compatibility: Optimized for Myford lathes and the ML7 series, making it a must-have accessory for hobbyists and professionals alike. Applications: Ideal for machining, drilling, and milling tasks where a precise 90° reference is required. Suitable for supporting small or irregularly shaped workpieces that demand secure clamping. Excellent for inspection and ensuring accurate alignment in various metalworking projects. Why Choose This Angle Plate? With its slim, slotted design and compatibility with popular lathe models, this angle plate is the perfect addition to your workshop. Whether you're a professional machinist or an enthusiastic DIYer, it offers the precision and reliability needed for high-quality results. Invest in the Slotted Slim Angle Plate today and take your machining capabilities to the next level!

$44.99 $39.99

-

Small 2" Inch Head Diameter Boring Head-Imperial Standards

Enhance your machining precision with our Small 2" Inch Head Diameter Boring Heads, meticulously crafted to meet Imperial Standards. Engineered for accuracy and efficiency, these precision tools are essential for any machining operation requiring meticulous bore sizing. Features: Imperial Standards: Designed to meet the exacting standards of Imperial measurements, ensuring precise bore diameters suitable for various machining applications. Compact Design: With a small 2" inch head diameter, these boring heads are ideal for operations where space is limited or intricate details are required. High-Quality Construction: Crafted from premium materials, these boring heads are durable and provide consistent performance over prolonged use. Versatile Compatibility: Compatible with a wide range of machining equipment, these boring heads seamlessly integrate into your existing setup for hassle-free operation. Fine Adjustment: Equipped with fine adjustment mechanisms, allowing for precise control over bore diameter, depth, and positioning. Smooth Operation: Engineered for smooth and stable operation, reducing vibration and ensuring superior surface finishes on your machined components. Wide Application: Suitable for various industries including automotive, aerospace, manufacturing, and more, these boring heads excel in diverse machining environments. Tools Specifications: Boring Head Diameter 2" Inches. Accepts 1/2" diameter shank tooling. Bore is precisely Ground, pls note. Imperial Standards ( 1 Division = 0.0005 Thou.). Maximum off 5/8" Invest in precision and reliability for your machining needs with our Small 2" Inch Head Diameter Boring Heads. Upgrade your workshop today! { Internal Ref. : VP }

$51.50 - $86.50

-

Small 2" Inch Head Diameter Boring Head-Imperial Standards With Plastic Box

Enhance your machining precision with our Small 2" Inch Head Diameter Boring Heads, meticulously crafted to meet Imperial Standards. Engineered for accuracy and efficiency, these precision tools are essential for any machining operation requiring meticulous bore sizing. Features: Imperial Standards: Designed to meet the exacting standards of Imperial measurements, ensuring precise bore diameters suitable for various machining applications. Compact Design: With a small 2" inch head diameter, these boring heads are ideal for operations where space is limited or intricate details are required. High-Quality Construction: Crafted from premium materials, these boring heads are durable and provide consistent performance over prolonged use. Versatile Compatibility: Compatible with a wide range of machining equipment, these boring heads seamlessly integrate into your existing setup for hassle-free operation. Fine Adjustment: Equipped with fine adjustment mechanisms, allowing for precise control over bore diameter, depth, and positioning. Smooth Operation: Engineered for smooth and stable operation, reducing vibration and ensuring superior surface finishes on your machined components. Wide Application: Suitable for various industries including automotive, aerospace, manufacturing, and more, these boring heads excel in diverse machining environments. Tools Specifications: Boring Head Diameter 2" Inches. Accepts 1/2" diameter shank tooling. Bore is precisely Ground, pls note. Imperial Standards ( 1 Division = 0.0005 Thou.). Maximum off 5/8" Invest in precision and reliability for your machining needs with our Small 2" Inch Head Diameter Boring Heads. Upgrade your workshop today!

$67.99 - $69.99

-

Small 38 mm Head Diameter Boring Heads-Metric Standards

A boring head is a versatile machining tool primarily used to enlarge, refine, and accurately size existing holes or cavities in workpieces. It achieves this by mounting on milling machines or machining centers and using various cutting tools such as boring bars or inserts. The main purpose of a boring head is to create precise internal dimensions with tight tolerances and smooth finishes Achieve precise and accurate boring operations with our Micro 38 mm Head Diameter Boring Heads. Designed to meet metric standards, these boring heads are perfect for fine-tuning holes in various machining projects, offering exceptional performance and reliability. Key Features: Head Diameter: 38 mm Metric Standards: Conforms to international metric standards for precision engineering Material: High-quality, durable steel construction Adjustment Range: Fine-tuning capability for accurate boring Versatile Compatibility: Suitable for use with various milling machines and boring tools Product Benefits: Precision Boring: Provides excellent accuracy for enlarging or finishing holes Durable Construction: Made from robust materials to ensure long-lasting performance and wear resistance Easy Adjustability: Allows for fine adjustments to achieve the desired boring diameter Versatile Application: Ideal for both professional machinists and hobbyists in metalworking and other machining tasks Smooth Operation: Designed for minimal vibration and smooth cutting action Specifications: Head Diameter: 38 mm Adjustment Range: Metric Standard 1 Division = 0.015 mm Material: High-quality steel Shank Type: MT2, MT3, R8 Applications: Suitable for precise boring in metalworking, engineering, and machining projects Ideal for creating and finishing holes with high accuracy Perfect for use in workshops, manufacturing plants, and DIY projects Why Choose Our Micro 38 mm Boring Heads? Our Micro 38 mm Head Diameter Boring Heads are engineered to deliver exceptional precision and reliability. Whether you are enlarging holes or finishing bores, these boring heads provide the accuracy and ease of use you need for professional-quality results. Built to meet rigorous metric standards, they are a valuable addition to any machinist's toolkit.

$19.99 - $82.50

-

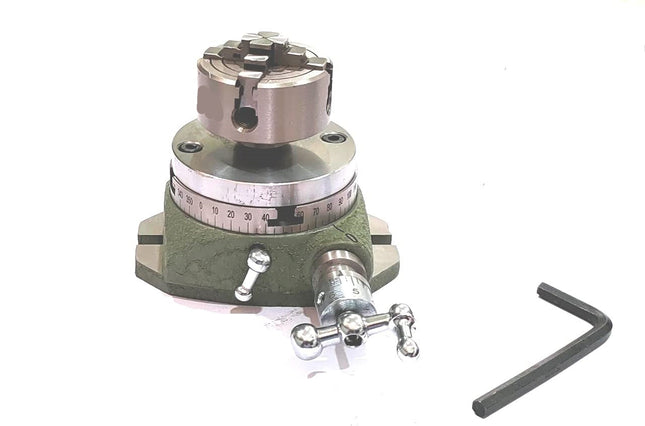

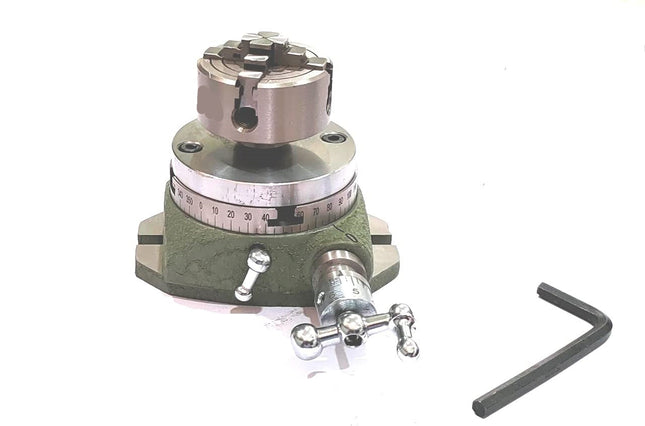

Small Chucks for 3" I 80 mm & 4" Inch I 100 mm Rotary tables and Mini Lathes

Purpose: The chuck for a rotary table typically has jaws or clamps that can be adjusted to securely grip the workpiece. It ensures that the workpiece remains stable and properly aligned during the machining process, allowing for accurate and consistent results. This is especially important for tasks that require precise positioning or multiple machining operations on different sides of the workpiece. Versatile Chuck Set: Upgrade your rotary table or mini lathe with this set of small chucks designed to fit 3" (80 mm) and 4" (100 mm) machines, enhancing their functionality and versatility. Precision Engineering: Crafted with precision to ensure optimal performance, these chucks provide secure grip and smooth rotation, essential for accurate machining and turning operations. Durable Construction: Made from high-quality materials, these chucks are built to withstand the rigors of machining tasks, ensuring long-lasting durability and reliability. Easy Installation: Simple to install and compatible with most rotary tables and mini lathes, these chucks allow for quick setup and seamless integration into your workshop or machining setup. Wide Application: Ideal for a variety of machining projects, these chucks enable you to securely hold workpieces of different shapes and sizes, expanding the capabilities of your rotary table or mini lathe. Compact Design: With their small size, these chucks are perfect for use with compact machinery, allowing you to maximize space efficiency in your workshop without sacrificing performance. Enhanced Efficiency: By providing a secure and stable grip on workpieces, these chucks help improve machining accuracy and efficiency, allowing you to achieve professional results with ease. Professional Results: Whether you're a hobbyist or a professional machinist, these small chucks are essential tools for achieving precision and accuracy in your machining and turning projects. {Internal Refence: HM}

$39.99 - $57.90

-

Small Chucks for 3" I 80 mm & 4" Inch I 100 mm Rotary tables with Steel Back Plates and Mini Lathes

The chuck for a rotary table typically has jaws or clamps that can be adjusted to securely grip the workpiece. It ensures that the workpiece remains stable and properly aligned during the machining process, allowing for accurate and consistent results. This is especially important for tasks that require precise positioning or multiple machining operations on different sides of the workpiece. Enhance the precision and versatility of your rotary tables and mini lathes with our high-quality small chucks. Designed for 3" (80 mm) and 4" (100 mm) rotary tables, these chucks come with durable steel back plates, ensuring a secure and reliable fit for various machining tasks. Key Features: High-Quality Construction: Crafted from premium-grade steel, our chucks offer exceptional durability and longevity. The steel back plates ensure a robust connection to rotary tables and mini lathes. Precision Engineering: Engineered for high accuracy, these chucks provide excellent concentricity and grip. Ideal for precise machining operations requiring tight tolerances. Versatile Compatibility: Suitable for 3" (80 mm) and 4" (100 mm) rotary tables. Compatible with a wide range of mini lathes, making them a versatile addition to your workshop. Easy Installation: Designed for quick and straightforward installation, saving you valuable time and effort. Includes all necessary mounting hardware for hassle-free setup. Secure Grip: Features high clamping force to securely hold workpieces in place during machining. Reduces the risk of slippage and enhances safety. Technical Specifications: Chuck Sizes Available: 3" (80 mm) and 4" (100 mm) Material: Premium-Grade Steel Back Plate Material: Tool Steel Applications: Ideal for use in metalworking, woodworking, and hobbyist projects. Perfect for precision machining, turning, and drilling tasks on rotary tables and mini lathes. Package Includes: 1 x Small Chuck for 3" (80 mm) or 4" (100 mm) Rotary Table 1 x Steel Back Plate Mounting Hardware Why Choose Us: Customer-Centric Service: We are dedicated to providing exceptional customer support and ensuring your satisfaction. Expertise: With over a decade of experience in the machine tool accessories industry, we deliver products you can trust. Global Reach: Serving customers across the USA, India, and now expanding to the UK, we are committed to meeting your machining needs wherever you are. Order Yours Today: Upgrade your machining setup with our premium small chucks. Place your order now and experience the difference in quality and performance!

$49.99 - $62.50

-

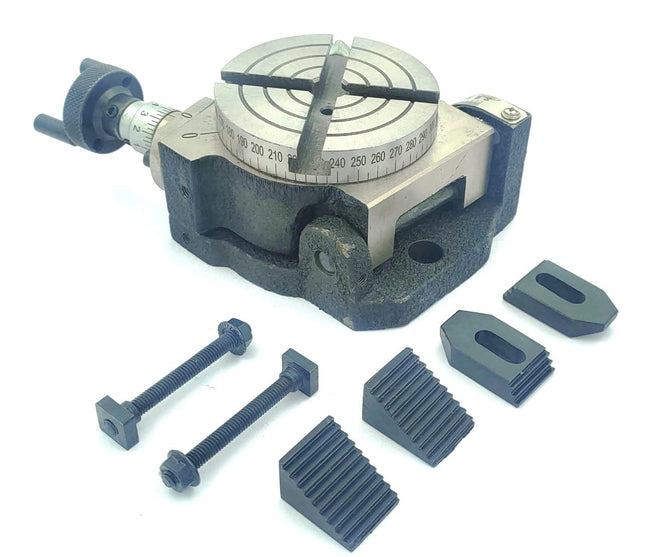

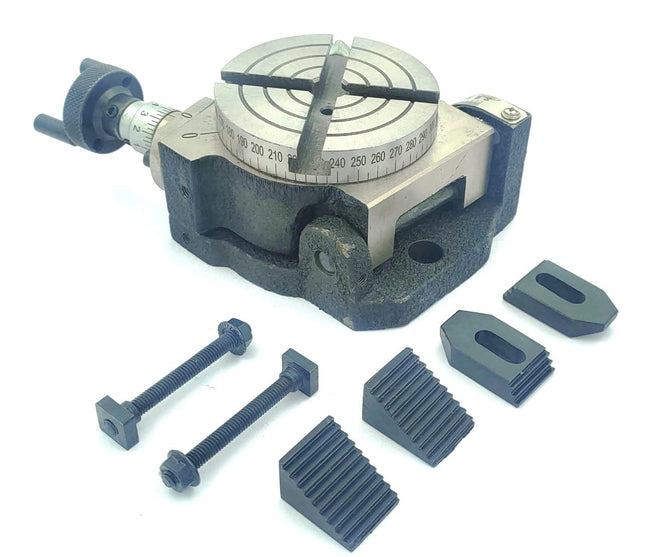

Small HV 3" Inch II 80 mm Rotary Milling Indexing Table with Clamp Kit

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. A clamp kit for a rotary table is used to secure workpieces onto the rotary table during machining operations. Rotary tables are often used in machining setups to enable circular cutting, hole drilling, and other operations around a fixed axis of rotation. Key Features: Compact & Low-Profile Design: Table Diameter: The rotary table features a 3-inch (80 mm) diameter, making it perfect for small-scale milling operations where space and precision are critical. Vertical Height: With a vertical height of just 1-5/8 inches, this rotary table maintains a low profile, enabling it to fit seamlessly into your existing setup while maximizing available workspace. Precision Engineering: Gear Ratio: The rotary table boasts a 36:1 gear ratio, ensuring precise control over the rotation. One full rotation of the handle results in a 10-degree rotation of the table, allowing for meticulous adjustments during milling tasks. Scale Calibration: The table scale is finely calibrated in 5-degree increments, providing clear and accurate angle measurements. This feature is particularly useful for tasks requiring high precision and consistency. Versatile Positioning: Horizontal & Vertical Use: This rotary table is designed for maximum versatility, capable of operating in both horizontal and vertical positions. This dual functionality allows for a wide range of applications, from simple flat milling to more complex angular cuts. Robust Construction: Base Dimensions: The base of the rotary table measures 4-1/8" x 3-1/4", providing a stable and secure platform for your work. The compact dimensions ensure that the table remains sturdy during use, minimizing vibrations and enhancing accuracy. T-Slots: The base is equipped with four 5/16" T-slots, allowing for secure clamping of workpieces. These slots are designed to accommodate various clamping setups, ensuring your workpiece remains firmly in place throughout the milling process. M6 Clamp Kit This M6 clamp kit is designed for use with 3" or 4" rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy. Ideal for use in machining setups requiring precise rotary table positioning.

$67.99 - $89.99

-

Small HV 3" Inch II 80 mm Rotary Milling Table

3" HV Milling Rotary Table available in Regular and Tilting Table All essential accessories are available for the 3-inch rotary table, including a tailstock, clamp kit, vice, and dividing plate. Our 3-inch dividing plate is an exclusive product, uniquely available only from us worldwide. Vertical & Horizontal Design Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. Low Profile A 3-inch rotary table being low profile means it fits easily in small spaces and compact machines. It allows better Z-axis clearance and is perfect for precise work on limited workspaces. Chamfered Sides Our 3-inch rotary table features a chamfered design, ensuring smooth edges for safer handling and easy alignment. The chamfered edges also enhance the aesthetic appeal while reducing the risk of edge damage during use. Wrinkle or Stoving Paint Our 3-inch rotary table is finished with durable wrinkle/ Stoving paint, providing a rugged texture that resists chipping and peeling. This ensures long-lasting protection and a professional look, even with regular use Oil Nipple & Locking Screw The rotary table is equipped with an oil nipple for easy lubrication, ensuring smooth and long-lasting rotation. It also features a locking screw to securely hold the table in position during machining for precise results. Precision Ground All working surfaces of the rotary table are precision ground to ensure high accuracy and smooth operation. This enhances alignment, reduces runout, and delivers consistent performance in precision machining tasks. Cap Grinded The rotary table comes with a cap ground finish, providing a smooth, flat surface that enhances accuracy during setup. This precision finish ensures better contact with fixtures and improved machining consistency. Gun Metal Gear The rotary table features a gunmetal gear, known for its excellent wear resistance and smooth operation. This ensures reliable performance, reduced friction, and a longer lifespan, even under continuous use. 3" Vertical & Horizontal Tilting Rotary Table The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from casting with high quality. They are are very popular on the market for their superior performance, excellent design and reasonable cost. Remarkable Quality Excellent Precision Multiple Application Vertical & Horizontal Design Specifications Table Diameter: 3" Worm- Gear Ratio - 36:1 Total Height when laid flat is 2-7/16" ( 62 mm ) Center Height in vertical position: 2-17/32" (61.5 mm approx) Can be clamped vertically and horizontally both ways. Base Dimensions : 100 x 105 mm with 2 x Drills (8 mm diameter) at a PCD of 82 mm approx. Weight of the Rotary Table : 2.700 Kgs. 3" Vertical & Horizontal Regular Rotary Table The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from casting with high quality. They are are very popular on the market for their superior performance, excellent design and reasonable cost. Remarkable Quality Excellent Precision Multiple Application Vertical & Horizontal Design Specifications Table Diameter: 3" Vertical Height: 1-5/8 inches Horizontal Height: 44 mm Gear Ratio - 36:1 Base Dimensions: 4. 1/8" x 3. 1/4" 4 T-Slots: 5/16"

$53.99 - $79.99

-

Small Slim Body Precision Triple Bearing Revolving Live Center Under 10 Micron Run-Out & 1500-1800 RPM

Use of product- Introducing our Small Slim Long Body Triple Bearing Live Revolving Center - MT2, engineered to precision for enhanced performance in your machining tasks. Crafted with high-grade materials and featuring cutting-edge triple-bearing technology, this revolving center ensures smooth rotation and unparalleled stability during operation. Key Features: Used for: A live center or revolving center is constructed so that the 60° center runs in its own bearings and is used at the non-driven or tailstock end of a machine. It allows higher turning speeds without the need for separate lubrication, and also greater clamping pressures. Triple Bearing Design: Equipped with three precision bearings, this revolving center offers exceptional load-bearing capacity and reduced friction, resulting in smoother rotation and extended tool life. MT2 Shank: Designed with a MT2 shank, this live center is compatible with a wide range of lathes, ensuring versatility and ease of use across various machining applications. Slim Long Body: The slim and elongated body design provides improved access to the workpiece, allowing for precise machining even in tight spaces. This design also minimizes interference and enhances maneuverability. High-Quality Construction: Constructed from premium materials, including hardened steel components, this revolving center is built to withstand heavy-duty use and maintain consistent performance over time. Versatile Applications: Suitable for a variety of turning, milling, and grinding applications, this live revolving center is ideal for both professional machinists and hobbyists alike. Precision Machining: Engineered with meticulous attention to detail, this center ensures accurate centering of the workpiece, resulting in superior machining accuracy and surface finish. Easy Installation: Designed for hassle-free setup, this revolving center can be quickly installed and secured onto your lathe, allowing you to start machining with minimal downtime. Whether you're working on intricate woodturning projects or precision metal machining tasks, our Small Slim Long Body Triple Bearing Live Revolving Center - MT2 is the perfect companion for achieving exceptional results with ease and efficiency. Invest in quality, precision, and reliability for your machining needs. {Internal Reference; HM}

$26.50 - $28.99

-

Small Slim Long Body Triple Bearing Live Revolving Center- MT2

Introducing our Small Slim Long Body Triple Bearing Live Revolving Center - MT2, engineered to precision for enhanced performance in your machining tasks. Crafted with high-grade materials and featuring cutting-edge triple-bearing technology, this revolving center ensures smooth rotation and unparalleled stability during operation. Key Features: Triple Bearing Design: Equipped with three precision bearings, this revolving center offers exceptional load-bearing capacity and reduced friction, resulting in smoother rotation and extended tool life. MT2 Shank: Designed with a MT2 shank, this live center is compatible with a wide range of lathes, ensuring versatility and ease of use across various machining applications. Slim Long Body: The slim and elongated body design provides improved access to the workpiece, allowing for precise machining even in tight spaces. This design also minimizes interference and enhances maneuverability. Body Diameter is 32 mm. Overall Length is 130 mm High-Quality Construction: Constructed from premium materials, including hardened steel components, this revolving center is built to withstand heavy-duty use and maintain consistent performance over time. Versatile Applications: Suitable for a variety of turning, milling, and grinding applications, this live revolving center is ideal for both professional machinists and hobbyists alike. Precision Machining: Engineered with meticulous attention to detail, this center ensures accurate centering of the workpiece, resulting in superior machining accuracy and surface finish. Easy Installation: Designed for hassle-free setup, this revolving center can be quickly installed and secured onto your lathe, allowing you to start machining with minimal downtime. Whether you're working on intricate woodturning projects or precision metal machining tasks, our Small Slim Long Body Triple Bearing Live Revolving Center - MT2 is the perfect companion for achieving exceptional results with ease and efficiency. Invest in quality, precision, and reliability for your machining needs. {Internal Reference; HM}

$29.99 $26.99

-

Small Tool Pouch Utility Tool Organizer with Tape Measure Holder, Electrician Tool Pouch for Belt

【HIGH QUALITY MATERIAL】: This tool pouch is made of wear-resistant 1680D ballistic polyester fabric to ensure toughness and durability in a variety of work environments. 【4-POCKET DESIGN】: Each pocket of our belt tool pouch is closed. The main pocket is 3 inches wide and is suitable for tools such as wrenches and pliers. The front pocket has 3 compartments designed for screwdrivers and pencils. 【ADDITIONAL ACCESSORIES】: For the convenience of carrying your measuring tools, the utility pouch with belt clip is equipped with a tape measure holder.The clip is 1.5 inches wide and fits most tape measures. 【FLEXIBLE FASTENING METHODS】: To meet the wearing needs of different users, the mini tool pouch is equipped with a belt clip and belt loop. You can choose to use the belt clip to clip directly to your belt or pass the belt through the belt loop. 【WIDELY APPLICABLE】: This tool belt pouch is mainly suitable for professionals who need to carry and use a variety of tools frequently, such as carpenters, electricians, repairmen, builders, plumbers, etc.

$14.99

-

Small Watchmaker 2-3/4" (2.75 Inch) Rotary Table with 50 mm Chuck and Back Plate

The small watchmaker rotary table is a versatile tool with a multitude of uses. It's indispensable in precision watchmaking, enabling accurate drilling, milling, and engraving for crafting and repairing intricate watch components. Additionally, it's favored by jewelry makers for its ability to shape metals with precision, from setting stones to creating bespoke jewelry pieces. Small Watchmaker 2-3/4" (2.75 Inch) Rotary Table The small watchmaker rotary table is a versatile tool with a multitude of uses. It's indispensable in precision watchmaking, enabling accurate drilling, milling, and engraving for crafting and repairing intricate watch components. Additionally, it's favored by jewelry makers for its ability to shape metals with precision, from setting stones to creating bespoke jewelry pieces. Compact Design: Table Diameter of 2.75 inches (72 mm) and a height of 1.5 inches (39 mm) when laid horizontally, offering a space-efficient solution. Precision Performance: Worm-Gear Ratio of 1:48 ensures precise positioning, with each handle rotation turning the table by 7.5 degrees, ideal for intricate milling tasks. Versatile Utility: Preferred choice among Watchmakers, Jewelry Tools, Model Makers & Hobbyists for its versatility in engraving, drilling, cutting, and shaping small components. Robust Construction: Crafted with high-quality materials and precision machining, guaranteeing durability and reliability for professional workshops and hobbyist setups. Smooth Operation: Equipped with smooth ball bearings and precision gearing, enabling effortless rotation and stable operation for flawless milling results. User-Friendly: Designed with ergonomic handles and intuitive controls for ease of use, reducing operator fatigue during extended milling sessions. Trusted Performance: Trusted by professionals and hobbyists alike for consistent precision and reliability, meeting exacting standards for precision milling applications. Available in 2 slots and 4 slots 50 mm Chuck -3 Jaw Self Centering (M12 x 1) Caste Iron Body 50 mm 3 Jaws Self Chucks with Tool Steel Hardened Jaws Body Diameter 50 mm , Mounting thread M12 x 1 It can hold any long round bar up to 12 mm, which can pass through the chuck's bore. 50 mm Chuck -4 Jaw Self Centering (M12 x 1) Caste Iron Body 50 mm 3 Jaws Self Chucks with Tool Steel Hardened Jaws Body Diameter 50 mm , Mounting thread M12 x 1 It can hold any long round bar up to 12 mm, which can pass through the chuck's bore. 50 mm Chuck - 4 Independent (M12 x 1) Caste Iron Body 50 mm 4 jaw Independent Dog Chucks with Hardened Tool Steel Jaws Graded Caste Iron Body and Hardened Tool Steel Jaws Mounting thread M14 x 1, same as that of the Arbors. Jaws are Hardened & Precisely Ground. Great for Holding Small Jobs upto 12 mm diameter both for Metal or Wood Working

$119.99