Lathe Parts & Accessories

-

Buyohlic Shank 1/2" Quick Action Scissor Type Knurling Tool Holder Capacity 1/16-2.1/4" | Length: 6" | Hardened Steel Knurls

Precision Knurling Made Easy – Quick Action Scissor Type Knurling Tool Holder Engineered for Professional Results Designed for machinists and DIY metalworkers, this quick-action scissor type knurling tool holder offers reliable, consistent performance. The self-centering design reduces pressure on your lathe and workpiece, ensuring precise knurling every time. About the Brand Buyohlic is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Buyohlic is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Buyohlic's products are sold in more than 200 countries.

$49.99 $39.99

-

2-1/2" Inch Head Fly Cutter with R8 Shank (7/16" UNF Drawbar) & HSS M2 3/8" Sq x 4" Inch Tool Bit

A fly cutter is a machining tool used in milling operations to create flat surfaces or contours on a workpiece. It typically consists of a single-point cutting tool (like a lathe tool bit) mounted in a spindle or fly cutter arbor. The cutter rotates as it cuts, and the workpiece is typically moved underneath it on a milling machine table. High-Quality Fly Cutter Head: Precision-engineered 2-1/2" inch head fly cutter, perfect for surface milling and creating smooth, flat finishes on your workpieces. Durable R8 Shank: Comes with an R8 shank compatible with 7/16" UNF drawbars, ensuring a secure and stable connection to your milling machine for optimal performance. Versatile HSS Tool Bit: Includes a 3/8" square x 4" inch High-Speed Steel (HSS) M2 tool bit, known for its excellent toughness and wear resistance, ideal for a variety of cutting applications. Easy to Use: Designed for straightforward installation and adjustment, making it suitable for both professionals and hobbyists looking to achieve precise milling results. Efficient Performance: The combination of the fly cutter head and HSS tool bit allows for efficient material removal and a superior surface finish, reducing machining time and effort. Robust Construction: Made from high-quality materials to ensure long-lasting durability and reliability in demanding machining environments. Versatile Applications: Perfect for milling flat surfaces, facing operations, and removing large amounts of material, making it a versatile addition to your machining toolkit. Compatibility: Designed to work seamlessly with most milling machines that accept R8 shanks, providing flexibility and convenience in your machining operations. Package Includes: One 2-1/2" inch head fly cutter with R8 shank (7/16" UNF drawbar) and one HSS M2 3/8" square x 4" inch tool bit. Enhance your milling capabilities with this high-quality fly cutter set, designed for precision, durability, and ease of use. {Internal Reference: HM}

$49.99 $44.99

-

Non- Adjustable T-Parting Cut off Holder with Blade for Lathe Machine Tools

A parting cut off tool holder is used in machining to hold a parting tool, which is a type of cutting tool used to create deep grooves or part off a workpiece from a larger stock material. The parting tool holder securely positions the parting tool in the correct orientation for making precise cuts. This tool holder is commonly employed in lathe operations for tasks such as cutting off workpieces to a desired length or creating deep grooves for various purposes such as threading or separating parts. It provides stability and control during the cutting process, ensuring accurate and consistent results. Versatile Tool Holder: Lathe parting tool holder designed for precision cutting and parting operations on lathes. High-Quality Construction: Constructed from durable materials such as High Speed Steel for long-lasting durability and stability during machining operations. Secure Clamping Mechanism: Equipped with a secure clamping mechanism that firmly holds the cutting tool in place, minimizing vibrations and ensuring accurate cuts. Compatibility: Compatible with a wide range of lathe models and sizes, making it suitable for various machining applications in workshops or industrial settings. Easy Installation: Simple and straightforward installation process, with clear instructions provided for hassle-free setup on your lathe machine. Smooth Operation: Designed to deliver smooth and consistent cutting performance, enhancing efficiency and productivity in your machining projects. Compact and Space-Saving: Compact design saves space in your workshop or tool storage area, while still offering exceptional performance and functionality. Wide Application: Ideal for use in metalworking, woodworking, and other machining applications where precise parting and cutting operations are required. Professional-Grade Tool: Suitable for both amateur hobbyists and professional machinists alike, offering professional-grade performance at an affordable price point. Enhanced Control: Provides enhanced control and stability during cutting operations, resulting in cleaner cuts and reduced material waste. Reliable Performance: Engineered to deliver reliable performance even under demanding machining conditions, ensuring consistent results with every use. Tools Specifications:- 1 x blade (1/16" x 5/16" x 3-1/2") with 1 x holder (6 mm Shank) 1 x blade (1/16" x 5/16" x 3-1/2") with 1 x holder (8 mm Shank) 1 x blade (1/16" x 5/16" x 3-1/2") with 1 x holder (10 mm Shank) 1 x blade (1/8" x 3/4" x 6") with 1 x holder (12 mm Shank) 1 x blade (3/32" x 1/2" x 4-1/2") with 1 x holder (10 mm Shank) {Internal Reference: HM}

$17.90 - $22.99

-

BUYOHLIC INTERNATIONAL Adjustable T-Parting Cut off Holder with Blade for Lathe Machine Tools

Use of product- A parting cut off tool holder is used in machining to hold a parting tool, which is a type of cutting tool used to create deep grooves or part off a workpiece from a larger stock material. The parting tool holder securely positions the parting tool in the correct orientation for making precise cuts. This tool holder is commonly employed in lathe operations for tasks such as cutting off workpieces to a desired length or creating deep grooves for various purposes such as threading or separating parts. It provides stability and control during the cutting process, ensuring accurate and consistent results. Versatile Tool Holder: Adjustable lathe parting tool holder designed for precision cutting and parting operations on lathes. Adjustable Design: Features an adjustable design that allows for easy customization of tool height and angle, ensuring precise cutting performance. High-Quality Construction: Constructed from durable materials such as High Speed Steel for long-lasting durability and stability during machining operations. Secure Clamping Mechanism: Equipped with a secure clamping mechanism that firmly holds the cutting tool in place, minimizing vibrations and ensuring accurate cuts. Compatibility: Compatible with a wide range of lathe models and sizes, making it suitable for various machining applications in workshops or industrial settings. Easy Installation: Simple and straightforward installation process, with clear instructions provided for hassle-free setup on your lathe machine. Smooth Operation: Designed to deliver smooth and consistent cutting performance, enhancing efficiency and productivity in your machining projects. Adjustable Cutting Depths: Allows for precise adjustment of cutting depths, enabling users to achieve the desired level of precision and accuracy in their work. Compact and Space-Saving: Compact design saves space in your workshop or tool storage area, while still offering exceptional performance and functionality. Wide Application: Ideal for use in metalworking, woodworking, and other machining applications where precise parting and cutting operations are required. Professional-Grade Tool: Suitable for both amateur hobbyists and professional machinists alike, offering professional-grade performance at an affordable price point. Enhanced Control: Provides enhanced control and stability during cutting operations, resulting in cleaner cuts and reduced material waste. Reliable Performance: Engineered to deliver reliable performance even under demanding machining conditions, ensuring consistent results with every use. Tools Specifications:- 1 x blade (1/8" x 3/4" x 6") with 1 x holder (10 mm Shank) 1 x blade (1/8" x 3/4" x 6") with 1 x holder (12 mm Shank) 1 x blade (3/32" x 1/2" x 4-1/2") with 1 x holder (8 mm Shank) 1 x blade (3/32" x 1/2" x 4-1/2") with 1 x holder (10 mm Shank) {Internal Reference: HM}

$26.96 - $36.00

-

Precision run out under 10 micron multi point bullet live revolving center

Use of product-A multipoint revolving center, commonly known as a live center, serves as a vital component in machine tool applications, particularly within lathe operations. Mounted in the tailstock, it supports workpieces at the non-driven end, reducing deflection and vibration during machining, thereby enhancing surface finish and dimensional accuracy. By evenly distributing load and minimizing friction, it facilitates smooth rotation of the workpiece, crucial for turning, facing, drilling, and other lathe operations. Its interchangeable tips accommodate various workpiece shapes and sizes, ensuring proper centering and support, thus improving machining efficiency and accuracy. Overall, the multipoint revolving center plays a pivotal role in enhancing the quality and productivity of machining processes. Multi-Point Design: Experience superior stability and support with our multipoint revolving center. Equipped with multiple precision-ground points, it ensures even distribution of force and minimizes deflection, resulting in smoother cuts and finer finishes on your workpieces. Versatile Functionality: From light-duty turning to heavy-duty machining, our revolving center adapts to a wide range of applications with ease. Whether you're working with wood, metal, or composite materials, enjoy the versatility and flexibility offered by our multipoint design. Precision Machining: Achieve unparalleled accuracy and consistency in your lathe operations. Each component of our revolving center is precision-machined to tight tolerances, ensuring reliable performance and exceptional results with every use. Durable Construction: Built to withstand the rigors of continuous use, our revolving center is constructed from high-quality tool steel for maximum durability and longevity. The rugged housing and hardened steel points deliver unmatched strength and resilience, making it ideal for demanding machining tasks. This set is supplied in a plastic suitcase as advertised, and comes with 7 different tips- 5 x live centers, 1 x female center, 1 x pipe center tip with an ejecting key Easy Installation: Designed for hassle-free setup and operation, our revolving center features a user-friendly design that allows for quick and easy installation on your lathe. Simply secure it in place and enjoy seamless integration into your existing workflow. Smooth Revolving Action: Experience smooth and precise rotation with our revolving center, thanks to its high-quality bearings and efficient design. Whether you're turning cylindrical, conical, or irregular-shaped workpieces, enjoy consistent performance and effortless operation. Enhanced Productivity: Boost your productivity and efficiency with the reliability and precision of our multipoint revolving center. Spend less time on setup and adjustments, and more time on actual machining, allowing you to complete projects faster and with greater accuracy. {Internal Reference: HM}

$68.99 $58.50

-

Round Small Fly cutting tool set of 3 Pcs (3/8" Shank) with HSS Cutting Tool Bit (Head Diameter : 9/16" , 3/4" & 7/8" Inches)

About The Brand Buyohlic is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Buyohlic is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Buyohlic's products are sold in more than 200 countries.

$26.96

-

Fly Cutting Tool Set of 3 Pcs with HSS Tool Bit- 1/2" Inch Shank (Head Diameter 3/4", 1-1/8" & 1-1/2" Inches) With Wooden Stand

About The Brand Buyohlic is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Buyohlic is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Buyohlic's products are sold in more than 200 countries.

$29.99 $26.99

-

Speed Guide Circle Cutter with HSS Tool Bit

Precision Circle Cutter - 38mm (1.5 Inches) to 165mm (6.5 Inches) Diameter Achieve perfect circles effortlessly with our Precision Circle Cutter. This versatile tool is designed for cutting precise circular shapes in a variety of materials, providing accuracy and efficiency in your crafting and design projects. Specifications: Circle Diameter: 38mm (1.5 Inches) Maximum Circle Diameter: 165mm (6.5 Inches) Available in: MT2, MT3, R8 and straight shank Features: Adjustable Cutting Range: With a minimum circle diameter of 38mm (1.5 inches) and a maximum circle diameter of 165mm (6.5 inches), this circle cutter offers a wide range of cutting options to suit your specific needs. Versatile Applications: Whether you're working with paper, cardboard, fabric, leather, or other materials, this circle cutter delivers precise results for various crafting, sewing, and design projects. Available in various shanks like MT2, MT3, R8 and straight shank. Easy to Use: The circle cutter features a user-friendly design, making it easy to adjust the diameter and smoothly cut circles with minimal effort. Simply set the desired diameter, position the cutter, and rotate to create perfect circles every time. Durable Construction: Crafted from high-quality materials, including a sharp cutting blade and sturdy handle, this circle cutter is built to withstand frequent use and provide long-lasting performance. Multipurpose Tool: Ideal for hobbyists, artisans, designers, and professionals alike, this circle cutter is suitable for a wide range of applications, including crafts, scrapbooking, model making, sewing, and more. Upgrade your crafting and design capabilities with the precision and versatility of our Precision Circle Cutter. Whether you're creating intricate artwork or functional prototypes, trust this reliable tool to deliver exceptional results with every cut. {Internal Reference; HM}

$35.95 $32.50

-

Long Body Mini Revolving Live Center Centre 23 MM Diameter

Use of product- A Revolving center provides support for the workpiece during rotation on the lathe spindle. In a mini lathe, which is smaller and often used for hobbyist or small-scale machining projects, the revolving center helps maintain precision and stability while machining cylindrical or tapered workpieces. It reduces friction and ensures concentricity between the workpiece and the lathe spindle, enabling accurate and efficient turning operations. Specifications: Body Diameter: 23 mm Overall Length: 97 mm Morse Taper: MT1 Premium Construction: Constructed from high-grade tool steel, this revolving center ensures longevity and reliability, even under heavy usage. Precision Machining: Engineered with precision machining, this center provides accurate rotation and alignment, essential for intricate turning and shaping tasks. Smooth Operation: Equipped with precision double bearings, this revolving center offers smooth and consistent rotation, reducing friction and wear for optimal performance. Versatile Compatibility: Compatible with a wide range of mini lathes, this revolving center easily integrates into your existing setup, offering versatility for various projects. Enhanced Support: Designed with a pointed tip, this center provides enhanced support to your workpieces, minimizing vibration and deflection for superior results. Easy Installation: Simple to install and remove, this revolving center streamlines setup and ensures hassle-free operation, saving you time and effort. Multi-material Capabilities: Whether you're working with wood, metal, or other materials, this revolving center delivers consistent performance across a variety of applications. Compact Size: Its compact size makes it ideal for use with mini lathes, providing efficient turning capabilities without taking up excessive space in your workshop. Professional Results: By ensuring precise alignment and rotation, this revolving center helps you achieve professional-quality results, elevating the quality of your craftsmanship.

$21.99 $16.50

-

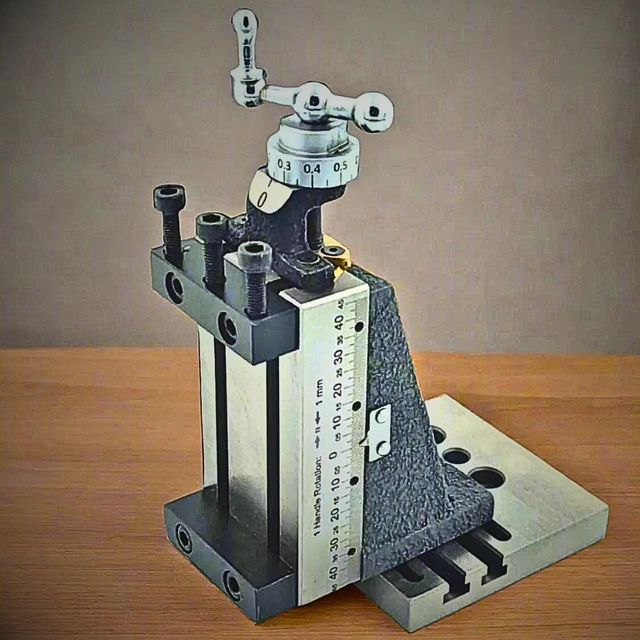

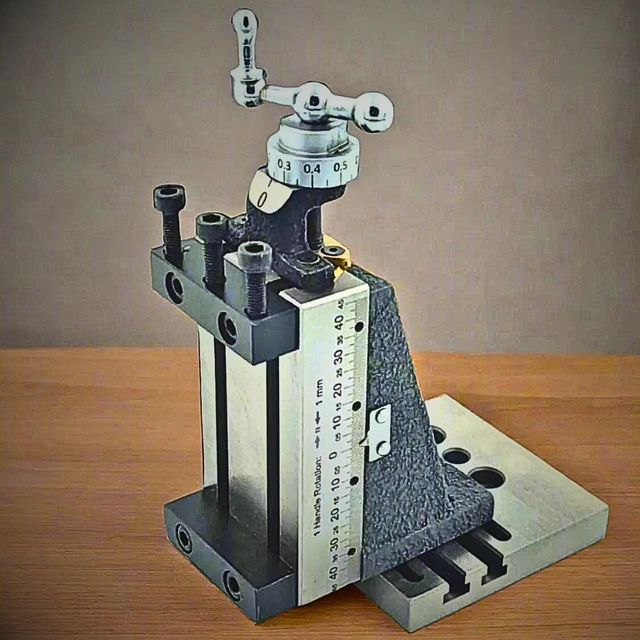

Lathe Vertical Milling Slide 4" x 5" Inches (100 x 125 mm) Fixed Base With Clamp 2 Slots

A fixed base vertical slide is used to hold workpieces securely in place during machining operations, ensuring stability and precision. It is typically mounted on a machine tool, such as a lathe or milling machine, and provides a stationary platform for the workpiece to be clamped or positioned. This slide helps maintain accurate alignment and control of the cutting tool, allowing for consistent and reliable machining results. Sturdy Vertical Slide: Our fixed base vertical slide is built to provide stability and precision for your machining operations. Crafted from durable materials, it offers reliable support for your workpieces. Generous Size: With dimensions of 4" x 5" inches (100 x 125 mm), this vertical slide provides ample space for a variety of machining tasks. Whether you're milling, drilling, or grinding, you'll have plenty of room to work with. Smooth Operation: Enjoy smooth and consistent performance with our vertical slide. It's designed to glide effortlessly along the base, ensuring precise control and accuracy during machining operations. Easy Adjustability: The vertical slide features adjustable components that allow you to fine-tune your setup for optimal results. Whether you need to adjust the height, angle, or position, you can easily make changes to suit your specific requirements. Versatile Compatibility: Compatible with a wide range of machines and accessories, our vertical slide is a versatile addition to any workshop. Whether you're using a milling machine, lathe, or other equipment, you'll find that this slide enhances your capabilities and expands your machining potential. Compact Design: Despite its generous size, our vertical slide has a compact design that won't take up unnecessary space in your workshop. It's easy to install and remove as needed, making it a convenient tool for your machining projects. Durable Construction: Built to withstand the demands of industrial use, our vertical slide is constructed from high-quality materials that are designed to last. You can trust that this slide will provide reliable performance for years to come. Precision Machining: Achieve precise results with our vertical slide, thanks to its rigid construction and smooth operation. Whether you're working on intricate parts or larger components, you can count on this slide to deliver accuracy and consistency every time. {Internal Reference: HM}

$139.99 $119.99

-

Buyohlic Set Of 2 High Speed Steel Double End Threading Tool

A Double End Internal External Threading High-Speed Steel (HSS) Tool Set is a specialized set of tools used for cutting threads on both the inside (internal) and outside (external) surfaces of cylindrical objects like pipes, rods, or bolts. These tools are typically used in machining processes such as turning, threading, or milling. Achieve precise and efficient threading operations with our Double End Internal External Threading HSS Tool Set. Crafted from high-speed steel (HSS), these double-ended tools are engineered for durability, ensuring extended tool life and consistent performance. Key Features: Versatility: Perform both internal and external threading operations with ease, eliminating the need for multiple tools and streamlining your machining process. Precision Cutting: Experience accurate and uniform thread cutting with sharp cutting edges that maintain their integrity even under demanding machining conditions. Diverse Applications: Suitable for use on various materials including steel, aluminum, brass, and plastics, making it an essential tool set for a wide range of industries and machining tasks. Longevity: Constructed from high-quality HSS, these tools offer exceptional wear resistance and heat tolerance, ensuring reliable performance over countless threading cycles. Double-Ended Design: Each tool features threading capabilities on both ends, maximizing efficiency and minimizing tool changes during machining operations. Standard Thread Profiles: Create threads with standard pitches and forms, ensuring compatibility with commonly used fasteners and components. Package Contents: 2 x Double End Internal External Threading HSS Tools 4mm, 6 mm, 8 mm, 10 mm, 12 mm. Storage case or organizer for convenient tool management and transportation Applications: Machining workshops Metalworking industries Automotive repair and manufacturing Aerospace engineering Plumbing and pipefitting DIY enthusiasts and hobbyists Upgrade your threading capabilities with our Double End Internal External Threading HSS Tool Set and experience enhanced productivity and precision in your machining operations. {Internal Reference: HM}

$13.99 - $23.99

-

Precision ER Collet with Revolving Live Center Lathe Machine Tools

Tool Specification: Body diameter is 44 mm. Bearing body length 50 mm. Overall Length is 145 mm. Shank is hardened and precisely ground. Used For: A revolving center tailstock, also known as a live center, is a crucial component in a lathe that supports and rotates the workpiece. It consists of a bearing-mounted center with a point that rotates with the workpiece, reducing friction and heat during turning operations. The revolving center tailstock is typically used for cylindrical workpieces and is driven by the rotation of the lathe spindle. This setup allows for smoother and more precise turning of the workpiece, especially when working with materials that require high precision and smooth finishes. High-Precision Machining: Engineered for precision machining applications, this ER collet revolving center ensures superior accuracy and repeatability, delivering high-quality machined components with tight tolerances. ER Collet System: Utilizes the popular ER collet system, providing a versatile and secure gripping mechanism for workpieces of various diameters, offering flexibility and efficiency in machining setups. Wide Range of Collet Sizes: Compatible with a wide range of ER collet sizes, allowing for the accommodation of different workpiece diameters, ensuring versatility and adaptability to diverse machining requirements. Quick Tool Changes: Facilitates quick and tool changes, thanks to the ER collet system's fast clamping and releasing mechanism, reducing downtime and improving productivity in machining operations. Robust Construction: Constructed from high-quality materials, including hardened steel and precision bearings, ensuring durability and long-lasting performance even under demanding machining conditions. Enhanced Stability: Features a robust bearing system and rigid construction to minimize vibration and deflection, providing stable support for workpieces during machining, resulting in improved surface finishes and dimensional accuracy. Adjustable Design: Offers adjustable components such as interchangeable collets and tailstocks, allowing for customization to accommodate various workpiece geometries and machining requirements, enhancing versatility and workflow efficiency. Efficient Lubrication System: Incorporates an efficient lubrication system to ensure smooth rotation and reduce friction, extending the lifespan of critical components and minimizing maintenance requirements, thereby maximizing uptime and productivity. Easy Installation and Setup: Designed for easy installation and setup, with user-friendly adjustment mechanisms and clear instructions, enabling operators to integrate the revolving center into machining setups quickly and efficiently, minimizing downtime and improving workflow efficiency. Wide Range of Applications: Suitable for a variety of machining applications, including turning, milling, drilling, and grinding, across diverse industries such as automotive, aerospace, and medical device manufacturing, making it a versatile tool for modern machining operations. Comprehensive Support: Backed by comprehensive customer support and after-sales service, including technical assistance, maintenance, and spare parts availability, ensuring peace of mind and maximum uptime for machining operations. Quality Assurance: Manufactured to stringent quality standards and subjected to rigorous testing procedures to ensure superior quality, reliability, and performance, meeting the exacting demands of precision machining environment {Internal Reference: HM}

$47.90 - $49.99