Business & Industrial

-

Set of 5 Pcs Center Punch-Imperial Standard Hard Metal-Wood Working Hand Tools

Use of product- A center punch is used to create a small indentation or mark on a workpiece, typically metal, to accurately guide a drill bit or other tool for drilling or machining operations. It helps ensure that the drill bit starts in the correct position and prevents it from slipping. Specifications: Material: High-Quality Hard Metal Standard: Imperial Set Includes: 5 Center Punches Head Types: Square Head, Round Head Sizes range: 1/16" to 5/32" Tip Diameter: Precision ground tips for accurate marking Features: Durable Construction: Made from hardened steel, these center punches are built to withstand heavy use and provide long-lasting performance. Precision Tips: Each punch features a precisely ground tip that creates accurate, clear indentations for drilling. Versatile Head Designs: The set includes both square and round head punches, catering to different preferences and applications. Ergonomic Design: The punches are designed for comfortable handling, reducing user fatigue during prolonged use. Variety of Sizes: The set includes punches of various lengths and tip diameters, suitable for different materials and project requirements. Benefits: Accurate Drilling: Prevent drill bits from slipping and ensure precise hole placement with clearly marked indentations. Enhanced Control: The ergonomic handles provide a firm grip, allowing for controlled and effective use. Versatility: Suitable for use on a variety of materials, including metal, wood, and plastic, making it an invaluable tool set for any workshop. Professional Quality: Designed to meet the needs of both professional craftsmen and DIY enthusiasts, ensuring reliable performance in all applications. Applications: Ideal for woodworking, metalworking, and various DIY projects. Suitable for marking drill spots on metal, wood, plastic, and other materials. Perfect for both professional use in industrial settings and home workshops. Available Head Types: Square Head: Provides a larger striking surface and is less likely to roll off surfaces, ensuring stability. Round Head: Offers a comfortable grip and is easy to handle, ideal for more delicate or detailed work. {Internal Reference: HM}

$11.99 $11.70

-

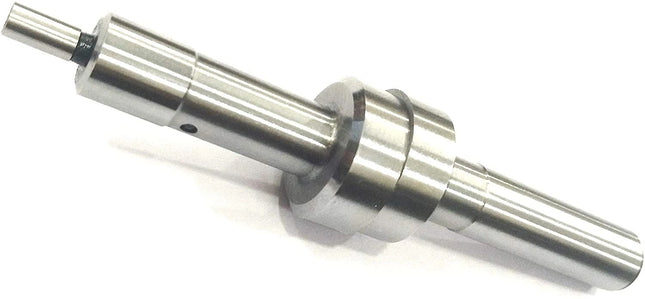

Set of 4 Pcs Pin Chuck Collet Vise Vice- Metric Capacity 0-4 MM

A pin chuck is a small, handy tool used primarily in woodworking and metalworking. It's essentially a miniature hand-held chuck that holds very small drill bits, taps, or other rotary tools securely. Pin chucks are particularly useful for delicate work where precision and control are necessary, such as jewelry making, model building, or fine detailing in woodworking. They allow the user to manually rotate and guide the tool with precision, making them suitable for intricate tasks where power tools might be too forceful or unwieldy. Set Includes: 4 precision pin chuck collet vises with varying capacities. Individual capacities: 0-0.8mm 0.8-1.3mm 1.3-3.1mm 3.1-4.8mm Material: High-quality hardened steel for durability and longevity. Corrosion-resistant finish to prevent rust and wear. Design & Construction: Ergonomic design for comfortable handling and precise control. Knurled bodies for a firm grip and easy tightening/loosening. Smooth and accurate threading ensures a secure fit for small drill bits, reamers, and other small tools. Versatility: Ideal for intricate and delicate work such as jewelry making, model building, electronics, and other crafts. Suitable for holding small tools with precision in various applications. Compatible with hand drills, drill presses, and rotary tools. Precision: Designed for high precision and accuracy in holding small diameter tools. Ensures stable and centered positioning to reduce run-out and improve work quality. Ease of Use: Easy to interchange collets for quick adjustments based on tool size. Lightweight and compact design for convenient storage and portability. Applications: Perfect for hobbyists, artisans, engineers, and professionals requiring detailed and accurate work. Ideal for drilling, reaming, and other precision tasks in various materials like metal, wood, and plastic. Dimensions: Compact size making it easy to handle and store. Each collet vise is precisely machined to ensure a tight and reliable hold. Additional Features: Comes in a protective case for easy organization and transport. Clear labeling of each collet size for quick identification. Quality Assurance: Backed by a satisfaction guarantee for peace of mind. Rigorous quality control to ensure consistency and performance. This set of 4 pin chuck collet vises provides a comprehensive solution for holding small diameter tools with precision and reliability. Perfect for detailed and delicate work, this set is an essential addition to any craftsman's toolkit. {Internal Reference: HM}

$12.95 $11.50

-

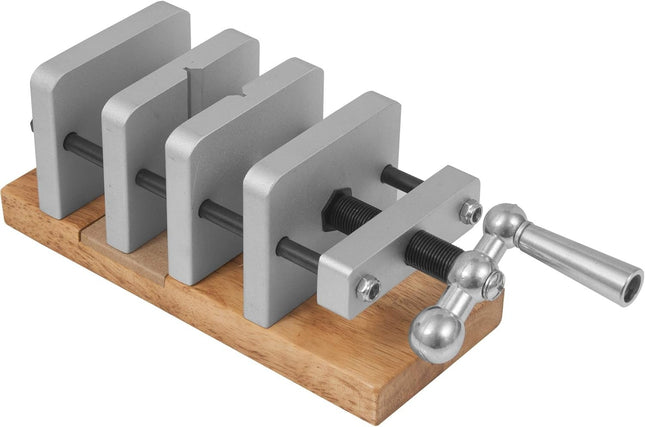

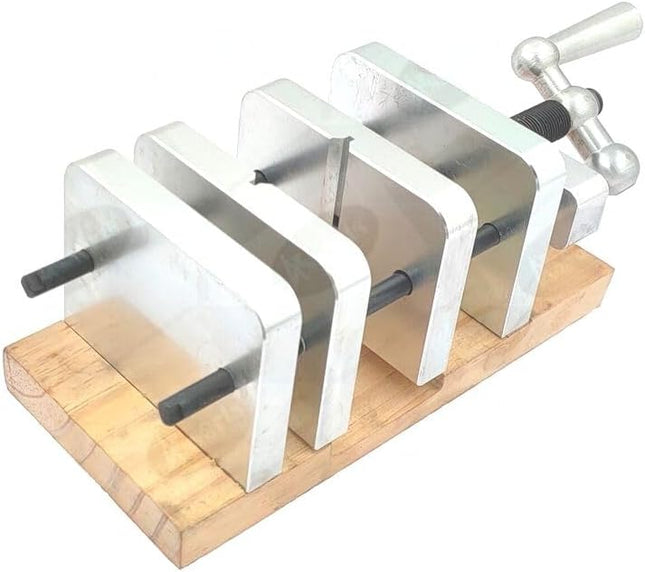

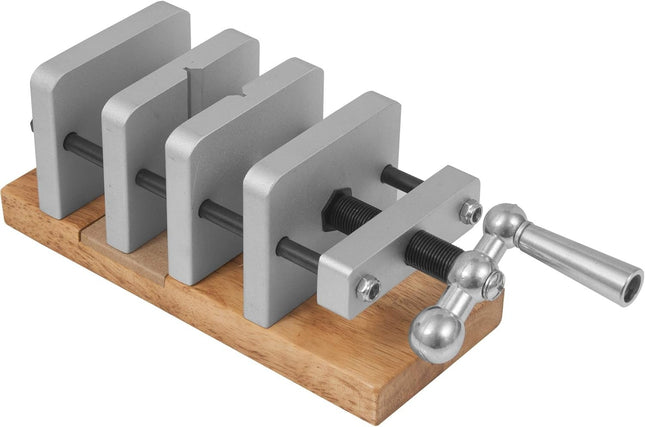

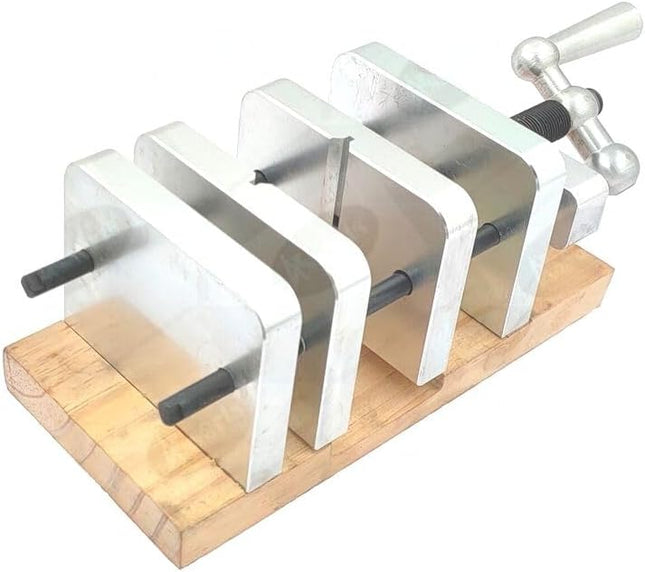

Pen Centering Vise Jig for Drilling Center Holes in Pen Blanks on a Drill Press

A Pen Centering Vise Jig is typically used in woodworking or crafting to assist in the assembly of pens, particularly those made on a lathe. It helps ensure precise alignment of pen components, such as the pen blank and the pen kit parts, during the assembly process. The jig holds the pen blank securely in place while allowing for accurate drilling and alignment of holes for the pen's components. This helps in achieving a professional and polished final product. Purpose: Designed specifically for accurately drilling center holes in pen blanks. Application: Ideal for pen makers and woodworkers who require precision in drilling operations. Key Features Precision Alignment: Ensures perfect centering of pen blanks for precise hole drilling. Reduces errors and improves the quality of finished pens. Robust Construction: Made from high-quality, durable tool steel to withstand repetitive use. Resistant to wear and tear, ensuring long-lasting performance. Adjustable Clamping Mechanism: Wooden base is removable and replaceable. If you need a larger base to clamp the vise to your drill press, simply remove the wooden base and replace it with a base made to your exact specifications Compatibility: Fits most standard drill presses. Can be used with a variety of pen blank materials, including wood, acrylic, and resin. Ease of Use: Simple setup process, making it accessible for both beginners and experienced users. Clear markings and guides to aid in accurate positioning. Safety Features: Secure clamping minimizes the risk of blanks slipping during drilling. Reduces the chances of injury and damage to the pen blanks. Enhanced Productivity: Speeds up the drilling process with reliable repeatability. Allows for batch processing of multiple blanks with consistent results. Portability: Lightweight design for easy transport and storage. Can be easily moved and set up in different workspaces. Benefits Improved Accuracy: Ensures that each pen blank is drilled precisely in the center, enhancing the overall quality of the pen. Time-Saving: Streamlines the drilling process, reducing the time required for setup and drilling. Versatility: Compatible with a wide range of pen blanks and drill presses, offering flexibility in use. Durability: Constructed from high-quality materials, the jig is built to last through extensive use. Specifications Material: High graded tool steel Holds blanks: 1-1/2" square The pen center vise includes a scrap board piece of mdf. It measures approximately 2" by 1/4". Wooden base is removable and replaceable. If you need a larger base to clamp the vise to your drill press, simply remove the wooden base and replace it with a base made to your exact specifications Additional Notes Ensure that the drill press is securely mounted and stable before use. Always wear appropriate safety gear, such as safety glasses and gloves, when operating the drill press and jig. Regularly check and maintain the jig for optimal performance and safety {Internal Reference: HM}

$57.99 $52.90

-

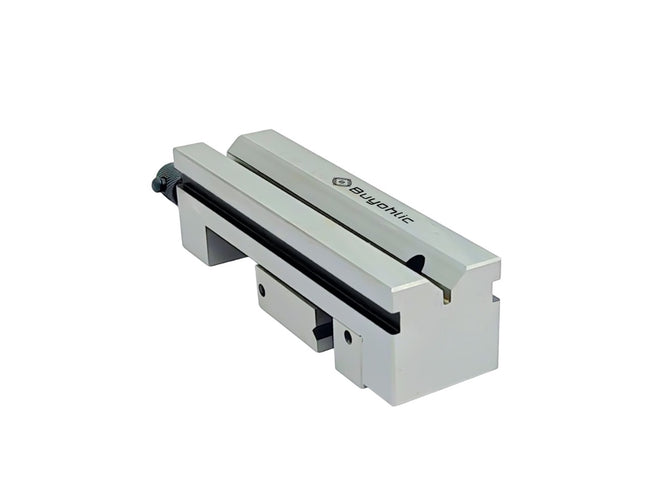

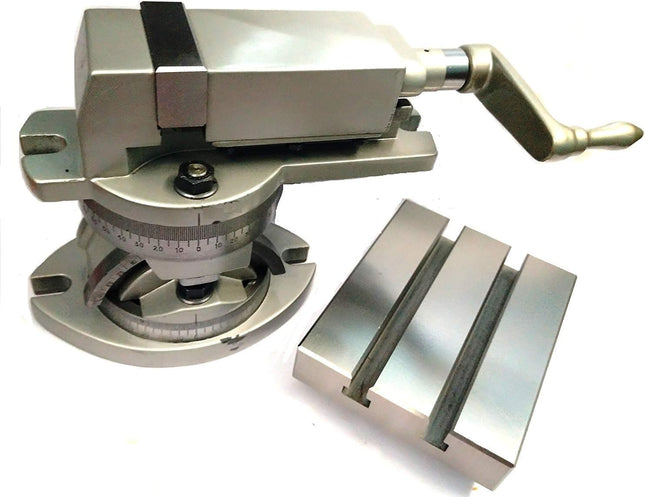

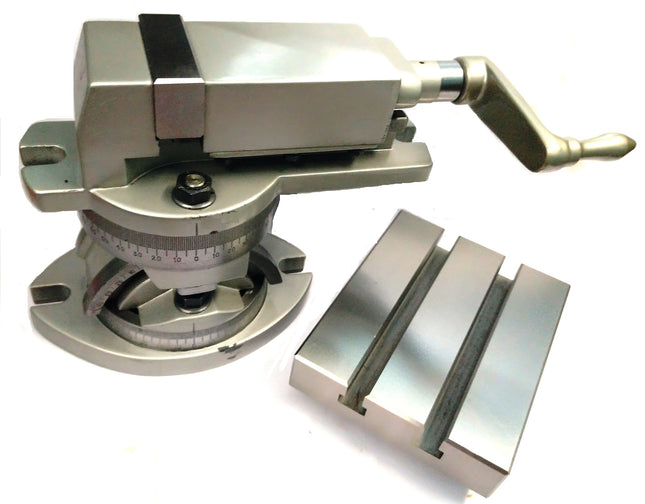

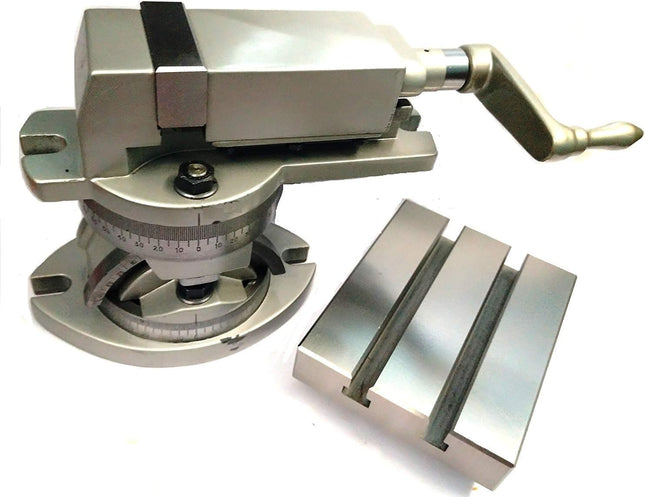

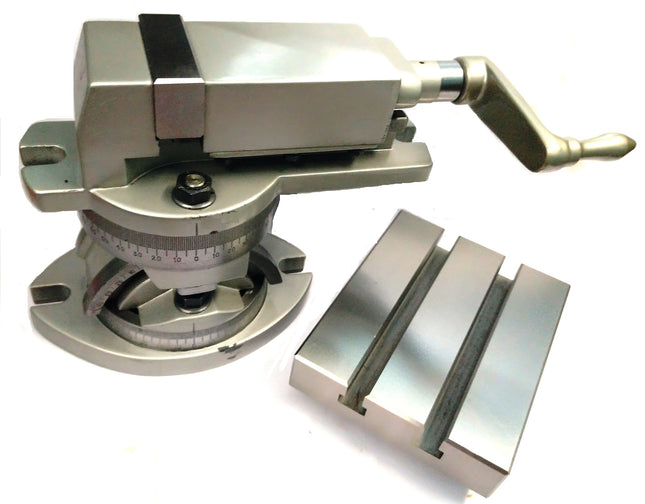

Hardened Tool Maker's Multi Purpose V Block Small Grinding Vice ( 33 mm Jaw Width)

A grinding vice, also known as a grinding clamp or grinding tool vice, is a device used to securely hold workpieces during grinding operations. It is specifically designed to grip and stabilize materials being ground on a surface grinder or a bench grinder. The primary purpose of a grinding vice is to provide a firm and stable grip on the workpiece, preventing it from moving or vibrating during the grinding process. This ensures accuracy, precision, and safety while grinding, allowing for the creation of smooth and uniform surfaces, precise angles, and consistent dimensions on the workpiece. Grinding vices are commonly used in metalworking, tool and die making, machining, and other industries where precision grinding is required. Product Name: Hardened Tool Maker's Multi-Purpose V Block Small Grinding Vice Jaw Width: 33 mm Material: High-quality hardened tool steel, heat-treated for enhanced durability and wear resistance. Dimensions: Overall length: 125 mm Width: 33 mm Jaw Opening: 80 mm ( Without the removable Jaw) & 42 mm (with the removable jaw) Jaw Depth: 13 mm Vee & clamp on reverse side will accept 35 mm diameter job. Surface Finish: Precision ground to a mirror finish for maximum flatness and smoothness, ensuring high accuracy during machining operations. V-Block Design: Incorporates a V-block design for holding cylindrical workpieces securely. Multi-purpose functionality allows for versatile applications, including grinding, milling, and drilling. Clamping Mechanism: Features a screw-type clamping mechanism for precise and adjustable clamping. Provides consistent and uniform pressure across the workpiece for secure holding. Base Design: Solid, stable base designed to prevent tipping and ensure stability during use. Equipped with mounting holes for secure attachment to workbenches or machine tables. Applications: Ideal for tool making, precision grinding, milling, drilling, and inspection tasks. Suitable for use in tool rooms, machine shops, and fabrication shops. Maintenance: Easy to clean and maintain. Resistant to rust and wear due to high-quality material and finish. Additional Features: Anti-slip serrated jaws for enhanced grip on workpieces. Precision lead screw for smooth operation and precise adjustments. Sturdy construction for long-lasting durability. Lightweight and compact design for easy handling and storage. Package Contents: 1 x Hardened Tool Maker's Multi-Purpose V Block Small Grinding Vice (33 mm Jaw Width) Warranty: Typically includes a 1-month manufacturer’s warranty. Customer Support: Comprehensive customer support available. Detailed instruction manual included for easy setup and use. Country of Manufacture: India Usage Instructions: Setup: Secure the vice to the workbench or machine table using the mounting holes. Adjustment: Turn the screw handle to open the jaws to the desired width. Clamping: Place the workpiece between the jaws, align it with the V-block if cylindrical, and tighten the screw handle until the workpiece is securely held. Operation: Proceed with grinding, milling, drilling, or inspection tasks as required. Maintenance: After use, clean the vice to remove any debris and apply a light coat of oil to prevent rust. This Hardened Tool Maker's Multi-Purpose V Block Small Grinding Vice (33 mm Jaw Width) is designed for precision and versatility, making it an essential tool for any workshop focused on high-accuracy machining tasks. {Internal Reference: HM}

$59.99 $49.50

-

Jaw Width 2'' Inches 50 mm Modular Machine Vice Cum Slotted Table

A modular milling vice is an advanced clamping tool designed for precision machining tasks. Its modular design offers unparalleled flexibility, allowing it to be configured and customized to meet the specific requirements of various machining operations. This vice is essential for securing workpieces during milling, drilling, tapping, and other machining processes, ensuring stability and accuracy. Key Features: Modular Design: Customizable Configuration: Easily add or remove modules to fit different workpiece sizes and shapes. Interchangeable Components: Utilize different jaws, risers, and accessories to adapt the vice to specific machining needs. High Precision: Accurate Positioning: Ensures precise and repeatable clamping, critical for high-precision machining. Stable Clamping: Reduces vibration and movement, enhancing the quality of the finished product. Robust Construction: Durable Materials: Made from high-quality materials such as hardened steel for long-lasting performance. Rigid Design: Provides strong clamping force to securely hold workpieces during intensive machining operations. Efficiency and Productivity: Quick Setup: Rapid changeover between different setups minimizes downtime. Batch Processing: Allows for multiple workpieces to be clamped simultaneously, increasing throughput. Versatility: Wide Application Range: Suitable for use in CNC machining centers and manual milling machines. Adaptability: Can be used for various machining operations including milling, drilling, tapping, and finishing. Enhanced Safety: Secure Clamping: Prevents workpieces from slipping or moving during machining, reducing the risk of accidents. Ergonomic Design: Easy to handle and adjust, improving operator safety and convenience. Specifications: Jaw Width: Available in 2" (50 mm) Clamping Force: High clamping force (e.g., up to 5000 kg) Material: Hardened steel, cast iron, or other high-strength materials Jaw Opening: Adjustable to accommodate different workpiece sizes Jaw Depth:- 25 mm Max. Opening: 2" (50 mm) Overall Height : 6" (150 mm) When Vice is clamp (& Table is removed) Base is 169.7 MM in Length x 88.5 mm Wide X 56 mm Details with Tee- Slotted Table Assembly Table Size : 4" x 5" (100 x 150 mm ) Overall Height : 5" (125 mm) When Boring Table is clamp (& Vice is removed) Tee Slot Width : 5/16" Applications: CNC Machining: Ideal for high-precision milling, drilling, and tapping operations in CNC machining centers. Manual Milling: Suitable for use with manual milling machines for various machining tasks. Batch Production: Perfect for production environments where multiple workpieces need to be processed efficiently. Prototype Development: Useful in prototyping where flexibility and quick adjustments are required. {Internal Reference: HM}

$199.00 $134.99

-

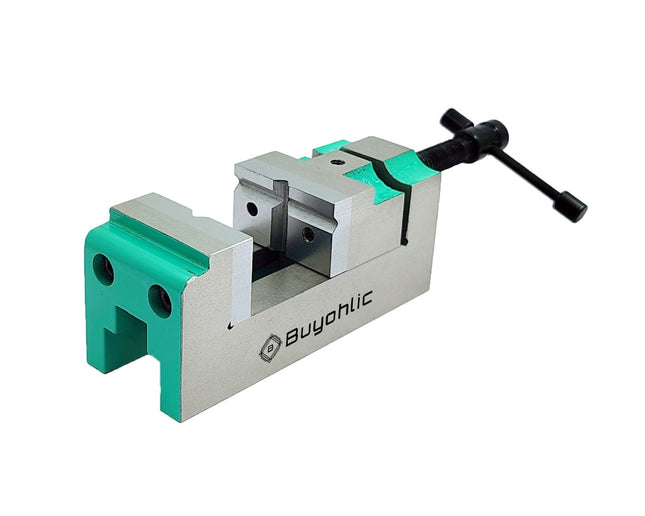

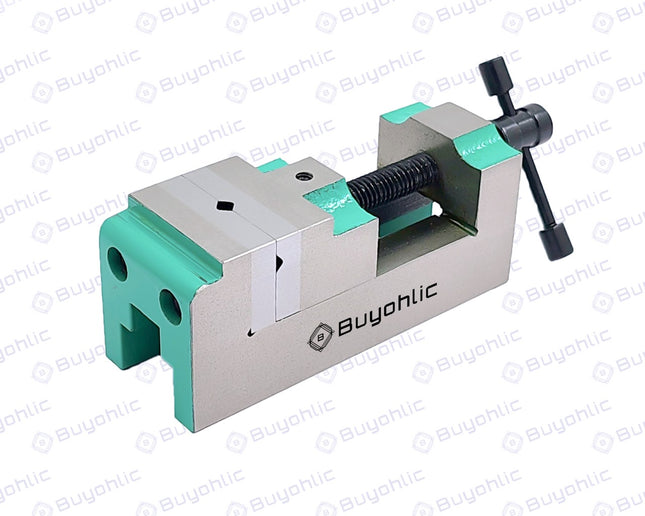

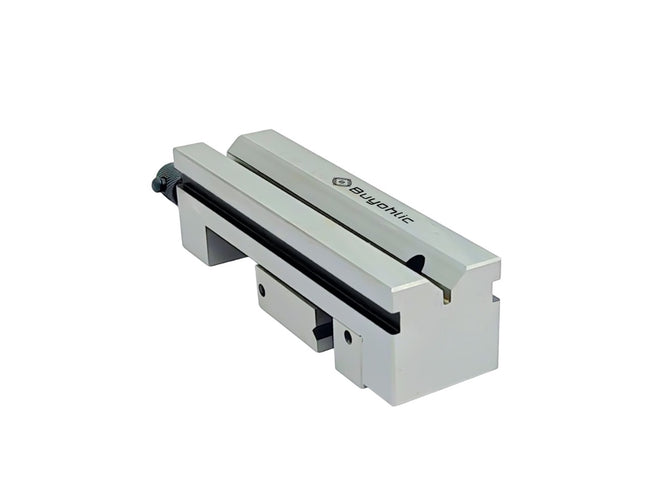

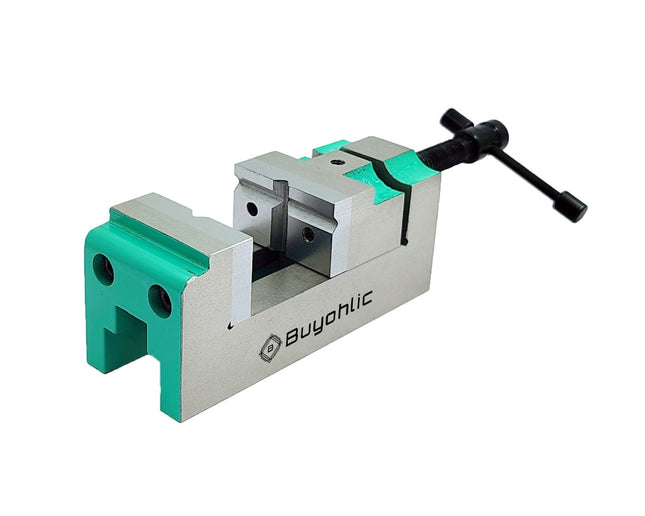

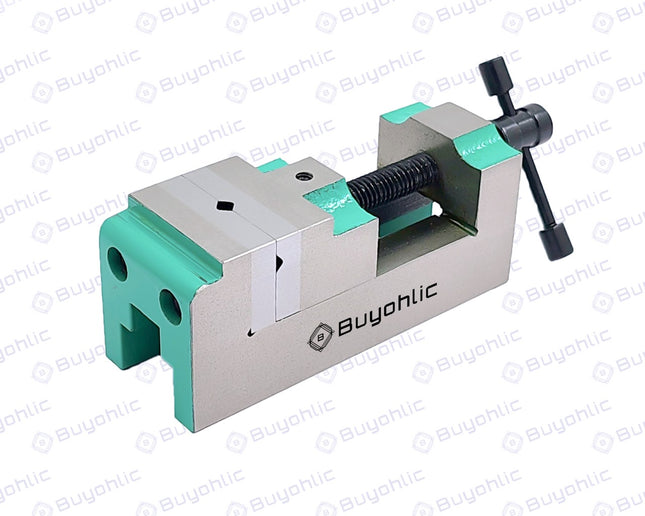

Self Centering Milling Machine Vice with Swivel Base - 2" Inch (Jaw Width 50 mm)

Self Centering Vice Vise Fixed Based-rigid & Tough A self-centering vice is designed to automatically align its jaws, ensuring the workpiece is perfectly centered without manual adjustment. This feature saves setup time and provides consistent clamping pressure on both sides, making it ideal for symmetrical and precision machining tasks. Its sturdy construction and smooth operation enhance both accuracy and efficiency in milling, drilling, and grinding applications. Automatic Jaw Alignment: Both jaws move simultaneously to center the workpiece automatically. Consistent Clamping Force: Ensures equal pressure on both sides for balanced holding. Time-Saving: Eliminates the need for manual centering, speeding up setup time. Ideal for Symmetrical Machining: Perfect for precision work requiring centered alignment. Versatile Application: Suitable for CNC, milling, drilling, and grinding machines. Buyohlic International Buyohlic is a leading brand that specializes in equipment and tools. Along with team of motivated employees, Buyohlic is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, out products are sold in more than 200 countries and regions with 10 million plus customers worldwide. Premium Tough Quality Incredibly Low Prices Fast & Secure Delivery 30-Day Free Returns 24/7 Attentive Service

$119.99 $99.99

-

Cast Iron Precision Swivel Universal Milling Machine Vice Vise Machine Tools

A milling vice, also known as a machine vice or mill vise, is a crucial tool used in machining operations to securely hold a workpiece in place while it is being worked on by a milling machine or other machine tools. It provides a stable, precise clamping mechanism that prevents any movement of the workpiece, ensuring accuracy and repeatability during milling, drilling, or other machining processes. The milling vice's robust construction and adjustable jaws allow it to accommodate various sizes and shapes of workpieces, making it an essential accessory for achieving precise and consistent results in metalworking and manufacturing tasks. Product Variants: 2" (50 mm) Jaw Width: 2 inches (50 mm) Jaw Opening: 2 inches (50 mm) Jaw Depth: 1 inch (25 mm) Base Dimension: 150 x 115 mm approx Overall Height at ideal 0 degree position is approx: 6" (150 mm) 3" (75 mm) Jaw Width: 3 inches (75 mm) Jaw Opening: 3 inches (75 mm) Jaw Depth: 1-1/4 inches (33 mm) 4" (100 mm) Jaw Width: 4 inches (100 mm) Jaw Opening: 4 inches (100 mm) Jaw Depth: 1-1/2 inches (38 mm) Base Dimension: 200 x 140 mm approx Overall Height at ideal 0 degree position is approx: 8" (200 mm) Features: Material: Constructed from high-quality cast iron, ensuring robustness and durability. Precision Engineering: Designed for accurate and stable clamping of workpieces during milling operations. Versatility: Suitable for various milling machine operations, offering reliable performance across different tasks. Jaw Adjustability: Provides ample jaw opening to accommodate a wide range of workpiece sizes. Benefits: Stable Clamping: Ensures secure holding of workpieces, reducing vibrations and improving machining accuracy. Durability: Cast iron construction ensures long-lasting performance even under heavy-duty use. Enhanced Productivity: Quick and easy setup reduces downtime and increases efficiency in milling operations. Wide Application: Ideal for professional machinists, workshops, and DIY enthusiasts

$121.50 - $369.00

-

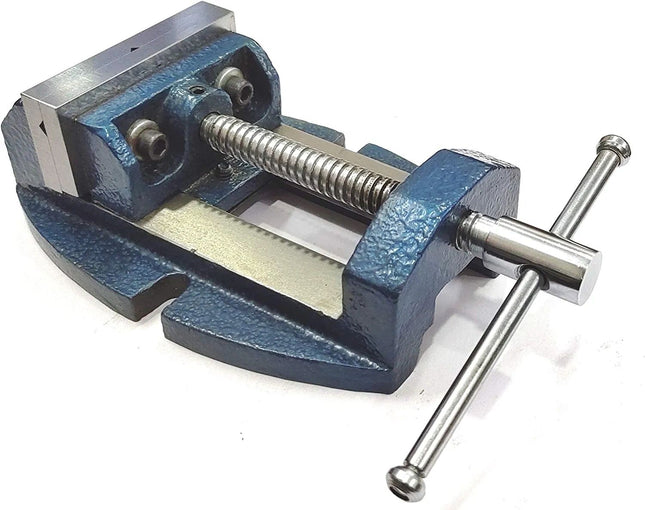

Caste Iron Small 1.5" Inches (38 mm) Jaw width Drill Press Vice Vise

A drill press vice is an essential tool used in conjunction with a drill press machine to securely hold workpieces in place during drilling, milling, or other machining operations. Its primary purpose is to provide stability and precision by firmly clamping the workpiece in position, allowing for accurate and repeatable drilling or milling. The vice typically features adjustable jaws that can accommodate various sizes and shapes of workpieces, ensuring versatility in its application. By securely holding the workpiece, the drill press vice enhances safety for the operator and improves the overall quality and precision of the machined parts. Heavy-Duty Construction: Crafted from robust steel, this drill press vice ensures durability and longevity, capable of withstanding rigorous use in various workshop environments. Precision Machined Steel Jaws: Featuring meticulously machined steel jaws, this vice offers superior grip and stability for securing workpieces during drilling operations, ensuring accurate and precise results. Adjustable Clamping Mechanism: Equipped with an adjustable clamping mechanism, this vice allows for quick and easy setup, enabling users to securely clamp workpieces of varying sizes and shapes with precision. Smooth Operation: Designed for smooth and effortless operation, this drill press vice facilitates efficient workflow, minimizing fatigue and enhancing productivity during drilling tasks. Versatile Application: Suitable for a wide range of drilling applications, including woodworking, metalworking, and more, this vice provides versatility and adaptability to diverse workshop needs. Stability and Security: With its sturdy base and reliable clamping system, this drill press vice ensures stability and security, preventing slippage or movement of workpieces during drilling operations, thus reducing the risk of accidents or errors. Corrosion-Resistant Finish: Finished with a corrosion-resistant coating, this vice offers protection against rust and corrosion, ensuring long-term performance and maintaining its appearance even in demanding working environments. Easy Installation: Designed for hassle-free installation, this drill press vice comes with all necessary hardware and instructions, allowing users to quickly set it up and start using it with minimal effort. Professional-Grade Quality: Engineered to meet the demands of professional craftsmen and hobbyists alike, this drill press vice combines high-quality materials, precision engineering, and ergonomic design to deliver reliable performance and exceptional results. Tools Specifications:- Jaw Width :38 mm, Maximum Jaw Opening: 38 mm, Jaw Depth: 22 mm, Base Dimensions: 105 mm long x 40 mm Width Whether you're a seasoned professional or a DIY enthusiast, this Drill Press Vice with Precision Steel Jaws is an essential tool for achieving accuracy, efficiency, and safety in your drilling projects. {Internal Reference: HM}

$59.99 $49.99

-

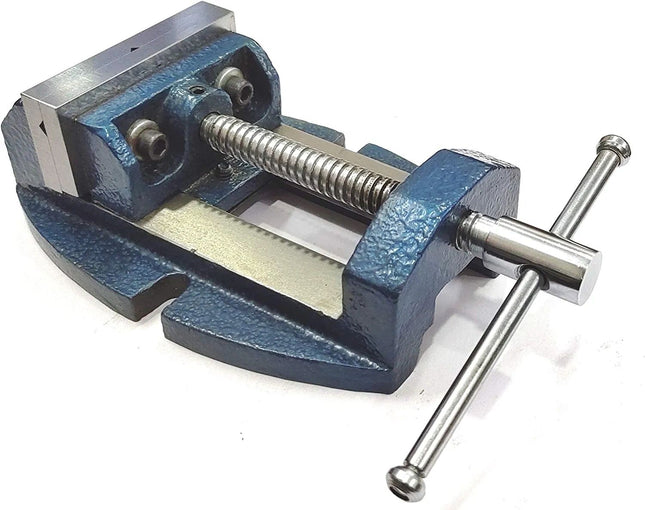

Drill Press Vice Precision-Steel Jaws

A drill press vice is an essential tool used in conjunction with a drill press machine to securely hold workpieces in place during drilling, milling, or other machining operations. Its primary purpose is to provide stability and precision by firmly clamping the workpiece in position, allowing for accurate and repeatable drilling or milling. The vice typically features adjustable jaws that can accommodate various sizes and shapes of workpieces, ensuring versatility in its application. By securely holding the workpiece, the drill press vice enhances safety for the operator and improves the overall quality and precision of the machined parts. Heavy-Duty Construction: Crafted from robust steel, this drill press vice ensures durability and longevity, capable of withstanding rigorous use in various workshop environments. Precision Machined Steel Jaws: Featuring meticulously machined steel jaws, this vice offers superior grip and stability for securing workpieces during drilling operations, ensuring accurate and precise results. Adjustable Clamping Mechanism: Equipped with an adjustable clamping mechanism, this vice allows for quick and easy setup, enabling users to securely clamp workpieces of varying sizes and shapes with precision. Smooth Operation: Designed for smooth and effortless operation, this drill press vice facilitates efficient workflow, minimizing fatigue and enhancing productivity during drilling tasks. Versatile Application: Suitable for a wide range of drilling applications, including woodworking, metalworking, and more, this vice provides versatility and adaptability to diverse workshop needs. Integrated Swivel Base: Featuring an integrated swivel base, this vice offers enhanced flexibility and maneuverability, allowing users to position workpieces at different angles for intricate drilling tasks. Stability and Security: With its sturdy base and reliable clamping system, this drill press vice ensures stability and security, preventing slippage or movement of workpieces during drilling operations, thus reducing the risk of accidents or errors. Corrosion-Resistant Finish: Finished with a corrosion-resistant coating, this vice offers protection against rust and corrosion, ensuring long-term performance and maintaining its appearance even in demanding working environments. Easy Installation: Designed for hassle-free installation, this drill press vice comes with all necessary hardware and instructions, allowing users to quickly set it up and start using it with minimal effort. Professional-Grade Quality: Engineered to meet the demands of professional craftsmen and hobbyists alike, this drill press vice combines high-quality materials, precision engineering, and ergonomic design to deliver reliable performance and exceptional results. SKU Jaw Width Jaw Opening Jaw Depth 30-DV-501 3” 75 mm 2-3/4” 70 mm 1-3/16” 30 mm 30-DV-502 4” 100 mm 4” 100 mm 1-1/2” 38 mm 30-DV-503 5” 125 mm 5” 125 mm 1-7/8” 48 mm Whether you're a seasoned professional or a DIY enthusiast, this Drill Press Vice with Precision Steel Jaws is an essential tool for achieving accuracy, efficiency, and safety in your drilling projects.

$84.98 - $97.98