Products

-

Mini Vertical Slide (90 x 50 mm) with Z Angle Plate -Instant Milling-on Small Bench Lathes

A vertical slide on the cross-slide enables the material to be raised or lowered as necessary. Widening the slot in a piece of material by machining along one edge with an end mill is an example. The same is true when all that is required is an initial height setting of work in relation to mill or cutter. The vertical slide admits of quick adjustment. A grinding vice, also known as a grinding clamp or grinding tool vice, is a device used to securely hold workpieces during grinding operations. It is specifically designed to grip and stabilize materials being ground on a surface grinder or a bench grinder. An angle plate is a work holding device used as a fixture in metalworking. A Z-type Angle plate is used to hold vertical slides square to the table during marking out operations. Mini Vertical Slide (90 mm x 50 mm) for Instant Machine Milling on Lathe Specifications: Vertical Travel: 40 mm – Allows for precise vertical adjustments, enhancing the flexibility of your milling operations. Base Dimensions: 50 x 55 mm – Provides a stable foundation for the vertical slide, ensuring secure attachment and reduced vibration. Sliding Table Dimensions: 90 x 50 mm – Offers ample work surface for small to medium-sized milling tasks. Dial Graduated to: 0-50 – Enables precise incremental adjustments for accurate milling operations. Features: High-Grade Casting: Constructed from premium-grade casting material, the vertical slide ensures durability and long-lasting performance under rigorous use. Smooth Finish: Engineered with a smooth surface finish, facilitating smooth and precise movement of the sliding table. Compact Design: Ideal for bench lathes with a swing of up to 150 mm, making it a perfect fit for compact workshop setups. Easy Installation: Designed for quick and straightforward installation on compatible lathes, allowing you to start milling operations with minimal setup time. Steel Grinding Vice 2" (50 mm) For Mini Lathe Vertical Milling Slide 50 mm (2" Inches) Jaw Width -Tool Steel -Precise Ground Vice Hole- Distance and bored to fit exactly on the Tee slots of our below shown mini lathe vertical slide. Horizontal and Vertical Vee in the moving jaws for holding Round jobs in this vice. Z Angle Plate Versatile Mounting Solution: Specifically designed for mounting vertical slides onto machine tools such as milling machines and lathes, this Z-type angle plate provides a versatile and sturdy platform for various machining operations. Precision Machining: Crafted from high-quality materials with precision machining, ensuring exceptional accuracy and stability during vertical slide mounting, allowing for precise machining of workpieces with minimal deflection. Optimal Design: The Z-type configuration offers optimal stability and rigidity, minimizing vibration and ensuring consistent machining performance, even during heavy-duty operations.

$99.99 - $139.99

-

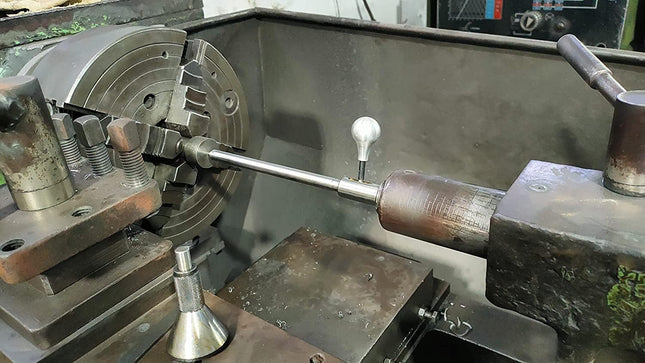

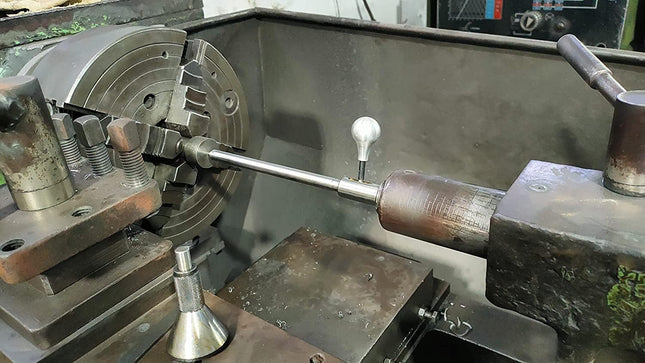

ML7 Super 7 Lathe Revolving Live Center Threaded With Self Centering Chuck-Lathe's Tailstock

a chuck and revolving center are used to secure and stabilize a workpiece from both ends during rotation, ensuring accurate alignment and reducing runout for precise machining operations. ML7 Super 7 Lathe Revolving Live Center with Chuck of Diameter 50 mm, 65 mm and 70 mm - Tailstock MT2 Shank and MT3 Shank in M12 x 1 & M14 x 1 Thread, High Precision Key Features & Description: Precision Crafted for ML7 Super 7 Lathe: Designed specifically for ML7 Super 7 lathes, this high-precision revolving live center boasts a runout within 0.01 mm, ensuring top-notch accuracy for your lathe applications. Shank with Thread: The revolving live center is equipped with an MT2 shank and M14 x 1 thread, compatible with the tailstock of your lathe for secure, seamless attachment. Includes Self-Centering Chuck: Comes with a self-centering chuck, which ensures precise alignment of your workpieces. The chuck body is made of durable cast iron, while the jaws are crafted from hard tool steel for extended wear resistance. Hardened Threaded Portion: The threaded portion of the revolving center is hardened to 40-42 HRC, delivering long-lasting durability and resistance to wear, even under heavy use. EN8D Tool Steel Body: The body of the revolving live center is manufactured from EN8D grade tool steel, offering high strength and impact resistance essential for demanding machining tasks. Optimized Bearing Design: Equipped with 2 ball bearings and 1 taper bearing, this live center is built to handle radial thrust effectively, ensuring smooth and reliable performance. Applications:Ideal for hobbyists, professionals, and machinists looking for high accuracy and stability in turning applications. This revolving live center is a perfect addition to any ML7 Super 7 lathe setup, providing outstanding reliability for intricate and precision-driven tasks. Package Includes: 1 x ML7 Super 7 Lathe Revolving Live Center with Self-Centering Chuck

$89.99

-

Morse Taper's Arbor to Mount JT2 Keyless Drill Chuck

Mount Type: Jacobs Taper #2 (JT2) – provides a secure friction-fit connection between the chuck and arbor/spindle. Capacity Range: 1-13mm Material: hardened steel for durability and wear resistance. Type: keyless Usage: Ideal for use in drill presses, milling machines, lathes, or other stationary equipment. Applications: Metalworking Woodworking Precision drilling Industrial and manufacturing tasks Chose from a variety of option of MT2/3 & R8 shanks - all having JT2 mounting tapers to mount the drill chuck along.

$52.99 - $57.90

-

Multi Face Interchangeable Texture Texturing Hammer for Fashion Jewelry Tools

A jewelry hammer is a specialized tool used in jewelry making and metalworking. It is typically smaller and lighter than traditional hammers, with finely polished heads to prevent marring or damaging delicate metals. Jewelry hammers are used for tasks such as shaping metal, texturing surfaces, riveting, and forming wire. They allow for precise control and delicate manipulation of metal, making them essential for crafting intricate jewelry pieces. Key Features: Interchangeable Faces: Comes with multiple textured faces, allowing you to create a variety of patterns and textures on your jewelry pieces. Easy Face Change: Simple mechanism to quickly and easily swap out hammer faces, ensuring seamless transitions between different textures. Ergonomic Handle: Designed with a comfortable, non-slip grip handle to reduce hand fatigue and provide better control during use. High-Quality Materials: Made from durable materials, ensuring longevity and consistent performance even with frequent use. Precision Crafting: Ideal for adding intricate textures and designs to metal surfaces, enhancing the aesthetic appeal of your jewelry creations. Specifications: Weight: 500 Grams Material: Hammer Head: Alloy Steel Handle: Wood Dimensions: Length: 9" Inches Width: 2-3/4'' Number of Interchangeable Faces: 9 Tips Tip Diameter: 3/4" Inches Approx. Ideal For: Jewelry Making: Perfect for creating unique textures and patterns on rings, bracelets, earrings, and other jewelry pieces. Metalworking: Suitable for various metalworking tasks, including embossing and imprinting designs on metal sheets. Craft Projects: Ideal for adding decorative touches to craft projects involving metal. Additional Benefits: Versatility: Multiple interchangeable faces provide endless possibilities for texturing and design. Portability: Compact and lightweight, making it easy to carry and store with your other jewelry tools. Durability: High-quality construction ensures the hammer withstands repeated use without wear or damage. Professional Finish: Helps achieve a professional, polished look on your jewelry pieces, enhancing their market value. Package Includes: 1 x Texturing Hammer Handle 9 x Interchangeable Texturing Faces Usage Tips: Face Selection: Choose the appropriate face for your desired texture and test on a scrap piece of metal before applying to your final piece. Maintenance: Regularly clean the faces and handle to maintain their condition and prevent rust or corrosion. Safety: Wear protective eyewear and gloves while using the hammer to prevent injury. Conclusion: The Multi Face Interchangeable Texture Texturing Hammer is an essential tool for any jewelry maker or metalworker looking to add unique and professional textures to their creations. With its ergonomic design, high-quality construction, and versatile interchangeable faces, this hammer offers endless possibilities for enhancing your jewelry designs and achieving stunning results every time. {Internal Reference: HM}

$29.95 $26.95

-

New Centralizer Tool Kit Includes 2MT Shank Centraliser & Engineer Bell Punch For Locating Work-piece Center on Independent Lathe Chuck

Use of Product- Its primary use is to provide a starting point for drilling holes with accuracy and prevent drill bits from slipping off-center. It's widely employed in metalworking, woodworking, jewelry making, and general DIY tasks to ensure precise hole placement for screws, fasteners, or decorative purposes. Key Features: Specifications: 2MT Shank Centralizer: Shank Type: 2 Morse Taper (2MT) Material: Hardened Steel OAL:- 285 mm Length of the needle pin: 185 mm Engineer Bell Punch: Max Diameter (Smaller Size): 35 mm Material: tool steel Precision Engineering: Ensures accurate center finding, crucial for subsequent machining processes. Reduces errors and enhances the quality of finished work by ensuring precise alignment. Versatility: Suitable for a wide range of applications in workshops, fabrication shops, and home DIY projects. Compatible with various types of round bars, including steel, aluminum, brass, and other metals. Ease of Use: User-friendly design makes it accessible even for those with limited experience in metalworking. Quick setup and operation save time and increase productivity. Benefits: Enhanced Productivity: Speeds up the center finding process, allowing for quicker project completion. Improved Accuracy: Ensures consistent and precise center finding, leading to better quality workpieces. Cost-Effective: Reduces material wastage by minimizing errors, saving both time and resources.

$49.95 $45.50

-

New Model Mini Lathe Milling Vertical Slide Tool Holder, Cast Iron Quick-Change Lathe Tool for Instant Milling, WM180V/WM210V

✅ Material: Made of cast iron, providing strength, durability, and resistance to wear and corrosion. Ensures a long service life for repeated use in various lathe operations. 📐 Specifications: Maximum clamping range: 75mm (2.95"), maximum lifting stroke: 84mm (3.3"), total height: 170mm (6.69"). Each rotation of the tool holder has an accuracy of at least 0.02mm for precise operation. 🛠️ Easy Operation: Dial design allows adjustment of clamping range with high accuracy. Each grid rotates at least 0.02mm, making operation simple and precise. ⚙️ Function & Design: Used to clamp the chuck, tailstock, turning tool, and milling chuck. Compact structure weighing 3kg (6.6lb), vertical sliding for fast clamping, suitable for lathes like WM180V and WM210V. 📦 Package Included: 1 piece of vertical lifting tool holder included.

$89.99

-

New Model Taper Turning Attachment With Scale For Lathe Tailstock

Taper turning is used to create tapered shapes or surfaces on cylindrical workpieces. It's commonly employed in manufacturing conical parts like shafts, spindles, and threads, as well as in woodworking for creating tapered legs. This process enables precise shaping and fitting of components in various industries, ensuring stability, functionality, and aesthetic appeal. Precision Taper Turning: Elevate your lathe operations with our versatile revolving center, designed for precise taper turning on a variety of materials. Wide Compatibility: Available in MT1, MT2, MT3, MT4, and straight shank options, our revolving center ensures compatibility with a range of lathe setups, providing flexibility for your machining projects. Smooth Rotation: Experience smooth and consistent rotation with our precision-engineered revolving center, facilitating uniform taper profiles and superior surface finishes. Optimal Support: The revolving center offers optimal support and alignment for your workpiece, reducing vibration and enhancing stability during machining for consistent and accurate results. Durable Construction: Crafted from durable materials, our revolving center is built to withstand the demands of machining, ensuring long-lasting performance and reliability in your workshop. Easy Installation: With a hassle-free installation process, our revolving center can be quickly mounted on your lathe, allowing you to start taper turning with minimal setup time. Professional Results: Whether you're a professional machinist or a hobbyist, our revolving center helps you achieve professional-quality taper turning results, enhancing the precision and efficiency of your lathe operations. Experience the versatility and reliability of our revolving center for taper turning, available in multiple shank options to suit your specific lathe requirements. {Internal Reference: HM}

$89.00 - $89.99

-

Buyohlic New Starter Engineer Kit (Try Squares, Center Squares, Carbide Scriber Pen, & Y Center Finder) Supplied With Plastic Case

Complete Starter Tool Kit: Includes 3 precision try squares (3", 4", and 6"), 1 center square with a 1.5"/80 mm blade, 1 carbide scriber pen, and 1 Y center finder with Plastic Suitcase. Versatile Applications: Ideal for hobbyists, machinists, and engineers, offering essential tools for accurate measurements and layout work. Durable Construction: Each tool is crafted for durability and precision, ensuring reliable performance in various workshop environments. Convenient Storage: Supplied in a quality plastic case with each tool set individually protected by Styrofoam casing for secure storage and easy organization. Professional Grade: Designed to meet high standards of craftsmanship and engineering, providing tools that deliver consistent accuracy and efficiency. Compact and Portable: Compact case design allows for easy transport and storage, making it suitable for both workshop and on-the-go use. Enhanced Accuracy: Carbide scriber pen for clear and permanent marking, and Y center finder for precise center location on cylindrical objects. Perfect Gift: An excellent choice for gifting to enthusiasts and professionals who appreciate quality tools for their projects. Customer Satisfaction: Backed by our commitment to quality and customer service, ensuring your satisfaction with every purchase.

$49.00 $45.50

-

New Taper Turning Attachment Off-setting Revolving Center Metric Tool With Plastic Suitcase

Precision Taper Turning: Elevate your lathe operations with our versatile revolving center, designed for precise taper turning on a variety of materials. Wide Compatibility: Available in MT1, MT2, MT3, MT4, and straight shank options, our revolving center ensures compatibility with a range of lathe setups, providing flexibility for your machining projects. Smooth Rotation: Experience smooth and consistent rotation with our precision-engineered revolving center, facilitating uniform taper profiles and superior surface finishes. Optimal Support: The revolving center offers optimal support and alignment for your workpiece, reducing vibration and enhancing stability during machining for consistent and accurate results. Durable Construction: Crafted from durable materials, our revolving center is built to withstand the demands of machining, ensuring long-lasting performance and reliability in your workshop. Easy Installation: With a hassle-free installation process, our revolving center can be quickly mounted on your lathe, allowing you to start taper turning with minimal setup time. Professional Results: Whether you're a professional machinist or a hobbyist, our revolving center helps you achieve professional-quality taper turning results, enhancing the precision and efficiency of your lathe operations. Experience the versatility and reliability of our revolving center for taper turning, available in multiple shank options to suit your specific lathe requirements. {Internal Reference: HM}

$98.00