Products

-

Tapping, Reaming & Threading Attachment Tailstock Die Holder Set

Die stocks (also known as die holders) are tubular parts that are used for fitting and turning dies when cutting or shaping materials. Die stocks are often used for cutting and threading metal objects like pipes. Versatile Functionality: Seamlessly switch between tapping, reaming, and threading operations with this comprehensive attachment set, saving time and effort in your machining processes. High-Quality Construction: Engineered from durable materials, each component is built to withstand rigorous use, ensuring long-lasting performance and consistent results. Precision Performance: Achieve accurate and uniform results every time, thanks to the precise design and construction of each attachment in the set. Easy Installation: Designed for quick and hassle-free setup, this attachment set integrates seamlessly with your existing machinery, allowing you to start working efficiently in no time. Tailored Compatibility: Compatible with a wide range of lathes and machining equipment, this set offers flexibility to accommodate various workshop setups and requirements. Enhanced Workshop Productivity: Streamline your machining processes and boost productivity with the efficiency and reliability of our Tapping, Reaming & Threading Attachment Tailstock Die Holder Set. Multipurpose Use: Whether you're a seasoned professional or a hobbyist, this versatile set caters to a diverse range of metalworking applications, making it a valuable addition to any workshop or tool collection. Die Holder Sizes: 13/16": Suitable for smaller threading tasks, providing precision and control. 1": Versatile size for a range of threading applications, balancing ease of use and functionality. 1-1/2": Ideal for larger threading requirements, ensuring robust performance and durability. Tap Wrench: Designed for holding and rotating taps during the tapping process. Tapping Capacity: 1/16" to 1/4": For fine, detailed tapping jobs, offering precision for small threads. 1/4" to 1/2": Suitable for medium-sized tapping needs, ensuring stability and strength. Buyohlic International's commitment to quality is evident in the design and manufacturing of this set, ensuring reliability and performance under demanding conditions. Whether used in industrial settings or workshops, this precision tool delivers consistent results, making it an essential addition to any machining toolkit.

$63.99 - $67.99

-

Tapping, reaming and threading die holder set for lathe tailstock with Plastic Box

Die stocks (also known as die holders) are tubular parts that are used for fitting and turning dies when cutting or shaping materials. Die stocks are often used for cutting and threading metal objects like pipes. Versatile Functionality: Seamlessly switch between tapping, reaming, and threading operations with this comprehensive attachment set, saving time and effort in your machining processes. High-Quality Construction: Engineered from durable materials, each component is built to withstand rigorous use, ensuring long-lasting performance and consistent results. Precision Performance: Achieve accurate and uniform results every time, thanks to the precise design and construction of each attachment in the set. Easy Installation: Designed for quick and hassle-free setup, this attachment set integrates seamlessly with your existing machinery, allowing you to start working efficiently in no time. Tailored Compatibility: Compatible with a wide range of lathes and machining equipment, this set offers flexibility to accommodate various workshop setups and requirements. Enhanced Workshop Productivity: Streamline your machining processes and boost productivity with the efficiency and reliability of our Tapping, Reaming & Threading Attachment Tailstock Die Holder Set. Multipurpose Use: Whether you're a seasoned professional or a hobbyist, this versatile set caters to a diverse range of metalworking applications, making it a valuable addition to any workshop or tool collection. Die Holder Sizes: 13/16": Suitable for smaller threading tasks, providing precision and control. 1": Versatile size for a range of threading applications, balancing ease of use and functionality. 1-1/2": Ideal for larger threading requirements, ensuring robust performance and durability. Tap Wrench: Designed for holding and rotating taps during the tapping process. Tapping Capacity: 1/16" to 1/4": For fine, detailed tapping jobs, offering precision for small threads. 1/4" to 1/2": Suitable for medium-sized tapping needs, ensuring stability and strength. Buyohlic International's commitment to quality is evident in the design and manufacturing of this set, ensuring reliability and performance under demanding conditions. Whether used in industrial settings or workshops, this precision tool delivers consistent results, making it an essential addition to any machining toolkit.

$79.50 $71.50

-

Tee Nuts For Rotary Tables & Vertical Slide

T-nuts, also known as tee nuts or blind nuts, are specialized fasteners used in woodworking, metalworking, and other applications where a threaded insert is needed. They are designed to create a strong and reusable female thread in materials like wood, plastic, or composite boards. Below is a detailed description of T-nuts: Key Features: Shape:T-nuts are typically flat, disc-shaped metal inserts with a threaded barrel extending from the center. Flange Design:They have a flange at the base, often with prongs or teeth that embed into the material for a secure hold. Some T-nuts have smooth flanges for non-wood applications. Threaded Barrel:The central barrel is internally threaded, allowing for the attachment of bolts or machine screws. Material:T-nuts are commonly made from steel, stainless steel, or brass, depending on the intended application. Steel T-nuts may have zinc or black oxide coatings for corrosion resistance. Sizes:They are available in various thread sizes (e.g., M4, M6, 1/4"-20) and barrel lengths to suit different material thicknesses. Applications: Woodworking:Used to secure components such as furniture parts, knobs, and handles by creating a strong threaded connection in wooden surfaces. Metalworking:Embedded into softer metals or composite materials to provide a durable thread. Rock Climbing Walls:Commonly used to attach climbing holds securely to plywood or other wall panels. Fixtures and Machinery:Ideal for joining and assembling mechanical components that require frequent disassembly.

$9.00 - $14.99

-

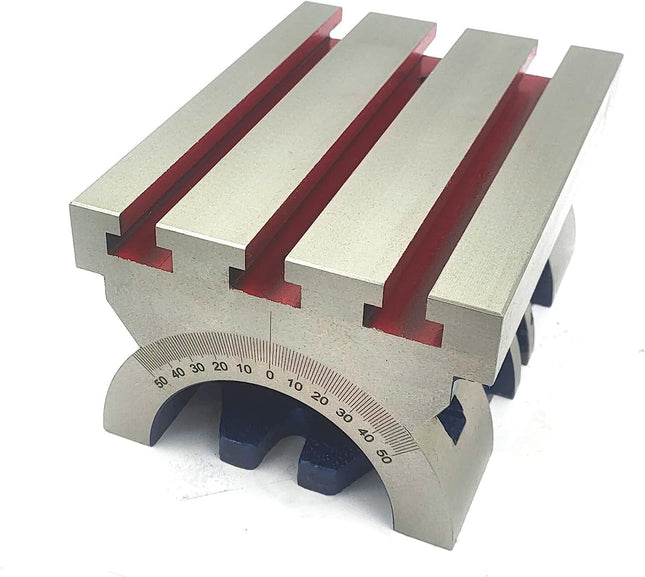

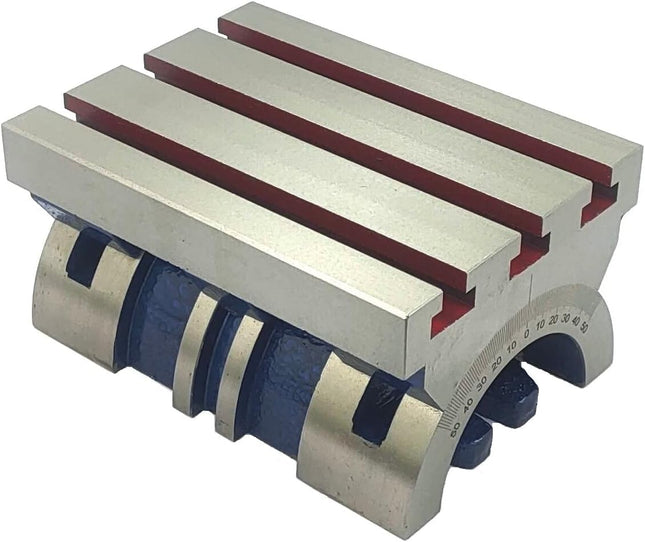

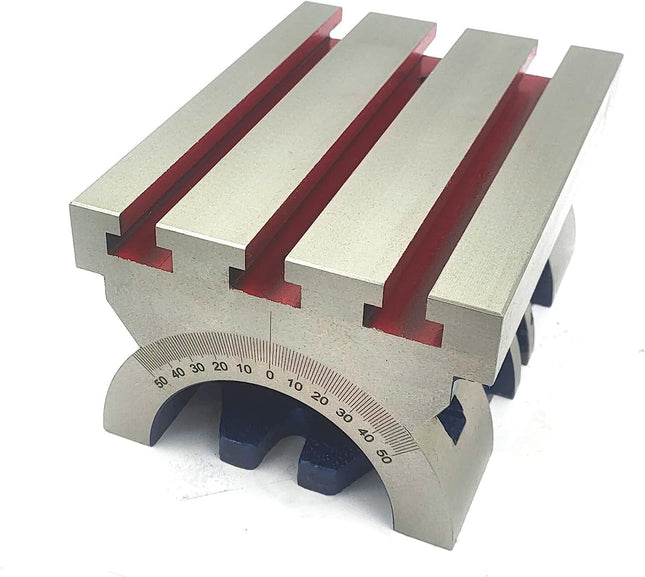

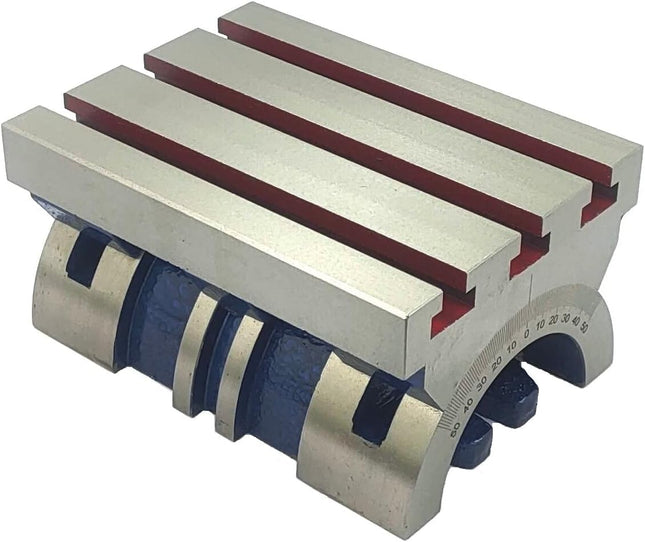

Tilting Table for Milling Machine

High-Precision Tilting Table for Milling Machines Use of product- A tilting table for a milling machine is an accessory that provides angular positioning for workpieces. It is used to tilt the workpiece to a specific angle, allowing for machining operations that require angled cuts, such as beveling, chamfering, and creating complex geometric shapes. Enhance your machining capabilities with our High-Precision Tilting Table, designed to deliver superior accuracy and versatility for your milling operations. Key Features: Adjustable Angle Range: Achieve precise angular positioning with a tilting range of 0° to 45°, perfect for beveling, chamfering, and complex angle cuts. Precision Scale: Features a clearly marked scale and adjustable stops for easy and accurate angle settings, ensuring repeatable precision. Sturdy Construction: Built from high-quality cast iron, this tilting table provides exceptional durability and stability, reducing vibrations and enhancing machining accuracy. Smooth Operation: Equipped with precision-ground ways and a high-quality lead screw for smooth and effortless angle adjustments. Versatile Mounting: Compatible with most milling machines, the tilting table includes multiple mounting slots for secure and flexible attachment of workpieces. Enhanced Productivity: Reduces the need for multiple setups, saving time and increasing efficiency in your machining processes. Applications: Ideal for creating angled cuts and complex geometric shapes. Perfect for precision engineering tasks in aerospace, automotive, and metalworking industries. Suitable for both professional workshops and hobbyist machinists seeking to expand their capabilities. Specifications: Material: High-quality tool steel Tilting Range: 45- 0-45 Degrees Table Size: 4" X 5" Inches/ 100 X 125 mm & 5" X 7" Inch / 125 X 175 mm For 4" x 5" Height in Horizontal Position 80 mm and for 5" x 7" is 90 mm Neatly Machined T Slots. Why Choose Our Tilting Table? Unmatched Precision: Ensure every cut is exact with our meticulously designed scale and adjustment mechanism. Robust Build: Count on a tilting table that withstands the rigors of daily use while maintaining top performance. Ease of Use: Simple adjustments and a user-friendly design make it easy to integrate into any milling setup. Upgrade your milling machine today with our High-Precision Tilting Table and experience a new level of accuracy and efficiency in your machining projects. Order now and take your craftsmanship to the next level!

$89.90 - $107.90

-

Tool Maker's Small Pin Type- Steel Grinding Precision Vice Vise

A grinding vice, also known as a grinding clamp or grinding tool vice, is a device used to securely hold workpieces during grinding operations. It is specifically designed to grip and stabilize materials being ground on a surface grinder or a bench grinder. The primary purpose of a grinding vice is to provide a firm and stable grip on the workpiece, preventing it from moving or vibrating during the grinding process. This ensures accuracy, precision, and safety while grinding, allowing for the creation of smooth and uniform surfaces, precise angles, and consistent dimensions on the workpiece. Grinding vices are commonly used in metalworking, tool and die making, machining, and other industries where precision grinding is required. Product Name: Grinding Precision Vice Vise Pin Type Material: High-quality tool steel, hardened and precision ground Dimensions: SKU Jaw Width Jaw Depth Jaw Opening Overall Height Overall Length 30-GV-201 38 mm 24 mm 75 mm 37 mm 150 mm 30-GV-202 75 mm 35 mm 100 mm 65 mm 178 mm 30-GV-203 95 mm 45 mm 125 mm 90 mm 235 mm 30-GV-204 150 mm 48 mm 175 mm 95 mm 330 mm Surface Finish: Precision ground to a mirror finish for maximum flatness and smoothness Clamping Force: Provides a robust clamping force suitable for various precision grinding applications Pin Type Mechanism: Features a pin-type mechanism for adjustable clamping Ensures uniform pressure distribution across the workpiece Allows for quick and easy adjustments Base Design: Solid base with optimal weight distribution to prevent tipping Equipped with mounting holes for secure attachment to workbenches or machine tables Applications: Ideal for precision grinding, milling, drilling, and inspection Suitable for use in tool rooms, machine shops, and fabrication shops Additional Features: Anti-slip serrated jaws for enhanced grip Precision lead screw for smooth operation Sturdy construction for long-lasting durability Package Contents: 1 x Grinding Precision Vice Vise Pin Type Customer Support: Comprehensive customer support available Detailed instruction manual included for easy setup and use Usage Instructions: Setup: Secure the vice to the workbench or machine table using the mounting holes. Adjustment: Insert the pin in the appropriate hole for desired clamping capacity. Clamping: Place the workpiece between the jaws and tighten the lead screw until the workpiece is securely held. Operation: Proceed with grinding, milling, or drilling operations as required. Maintenance: After use, clean the vice to remove any debris and apply a light coat of oil to prevent rust. This Grinding Precision Vice Vise Pin Type is designed for precision and durability, making it an essential tool for any workshop focused on high-accuracy machining tasks. {Internal Reference: HM}

$47.99 - $68.50

-

Tool Post Mini Vertical Milling Slide For Lathe Machine-Metalworking Tool

Tool Post Slide Structure Precision-guided vertical dovetail slide for accurate movement. Graduated dial enables manual depth control. Mounting slots and screws secure the slide to the lathe. Tool post bracket and solid base provide stable tool support. Applications Converts a lathe into a vertical milling setup. Enables precise vertical movement for milling tasks. Facilitates slotting, grooving, and surface milling. Includes a graduated dial for depth control. Mounts directly onto the lathe tool post. Expands machining capabilities in small workshops. Materials for design Base constructed from durable cast iron. Sliding components made of hardened tool steel. Rotary dial crafted from aluminium or steel. Pins made of brass or anodized aluminium. Fasteners use black oxide coated alloy steel. Features Provides vertical movement for machining operations. Features a micrometer dial for precise adjustments. Compatible with mini lathes and tool posts. Operated manually via dial or handwheel. Requires basic maintenance like lubrication. Customizable with additional attachments.

$67.90 $59.99

-

Tool Steel 60 Degree Dead Center Centre- lathe Drill, Mill, Grinder Tools

A dead center lathe tool is used to support and align workpieces in a lathe by providing a fixed point in the tailstock, ensuring the workpiece is stable and accurately aligned with the spindle axis. This support is crucial for maintaining rotational symmetry, reducing deflection and vibration, and achieving precise machining with a high-quality surface finish. By minimizing movement and ensuring proper alignment, the dead center plays a key role in producing concentric and uniformly cut parts. Precision Machining: Elevate your lathe operations with our high-quality lathe dead centers, available in MT1, MT2, MT3, and MT4 shanks to suit your specific needs. Versatile Shank Options: Choose from a range of shank sizes, including MT1, MT2, MT3, and MT4, ensuring compatibility with a variety of lathe setups. Robust Construction: Crafted from durable materials, our lathe dead centers are built to withstand the rigors of machining, ensuring long-lasting performance and reliability. Optimal Support: Designed to provide optimal support and alignment for your workpiece, our dead centers help minimize vibration and improve machining accuracy. Smooth Rotation: Experience smooth and consistent rotation with our precision-engineered lathe dead centers, facilitating precise turning and machining operations. Easy Installation: Featuring a hassle-free installation process, our lathe dead centers can be quickly and securely mounted on your lathe, allowing you to get to work with minimal setup time. Wide Application: Whether you're working on woodworking projects, metalworking tasks, or other machining applications, our lathe dead centers offer versatility and performance across a range of materials and projects. Upgrade your lathe setup with our precision lathe dead centers, available in MT1, MT2, MT3, and MT4 shanks, and experience enhanced machining accuracy and efficiency. {Internal Reference; HM}

$9.90 - $44.99

-

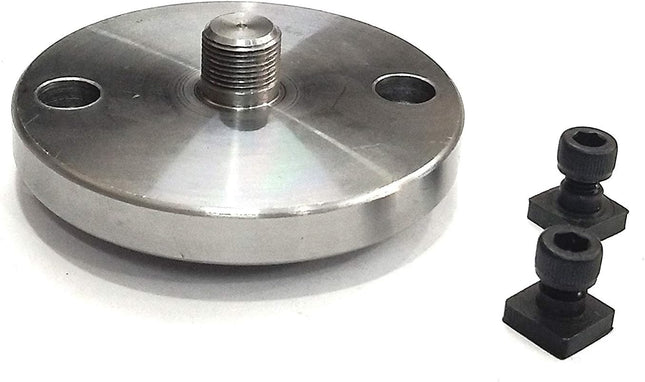

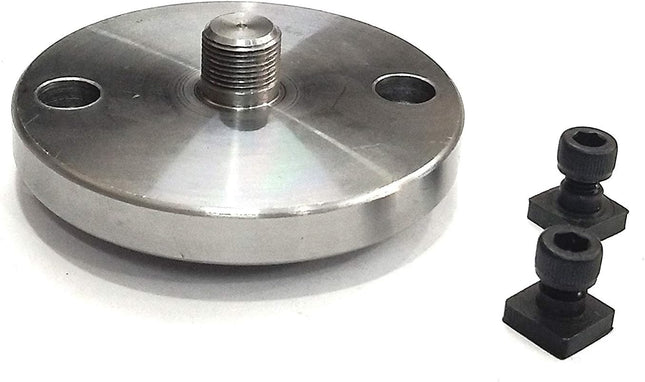

Tool Steel 70 mm Back Plates for Mounting Small Chucks on Rotary Tables

Back plates serve as mounting surfaces for workpieces or fixtures. They facilitate the secure attachment of the workpiece or fixture to the rotary table, enabling precise machining operations such as milling, drilling, or grinding. Additionally, back plates may incorporate features such as T-slots or mounting holes to accommodate different types of workpieces and tooling setups, enhancing versatility and accuracy in machining processes. Enhance the versatility and functionality of your rotary table with our precision back plate. Crafted from high-quality [Material], this back plate ensures reliable performance and durability for all your machining needs. Features: Robust Construction: Engineered from sturdy tool steel, our back plate is built to withstand heavy-duty machining operations, providing stable support for your workpieces. Precision Machining: Designed with meticulous attention to detail, our back plate offers precise alignment and compatibility with your rotary table, ensuring accurate machining results. Universal Compatibility: Compatible with a wide range of rotary tables, our back plate is a versatile addition to your workshop, catering to various machining projects. Easy Installation: Installing our back plate is quick and straightforward, allowing you to attach it to your rotary table effortlessly for immediate use. Secure Mounting: Equipped with sturdy mounting holes, our back plate ensures a secure and stable connection to your rotary table, minimizing vibrations during machining. Smooth Surface Finish: Finished with a smooth surface, our back plate provides an ideal mounting surface for your workpieces, reducing friction and enhancing machining precision. Size Options: 70 mm diameter back plate in M12 x 1 and M14 x 1 thread. Package Includes: [1] x Precision Back Plate for Rotary Table [3] x Tee Nuts Bolts Upgrade your machining capabilities with our precision back plate for rotary tables. Order now and experience enhanced accuracy and efficiency in your workshop! {Internal Reference: HM}

$14.50 $12.99

-

Tool Steel Drill Chuck Arbor Drill, Mill, Lathe Machine Tools

Use of product- A drill chuck arbor is an essential component used to connect a drill chuck to a machine tool, such as a milling machine, lathe, or drill press. The arbor serves as the intermediary between the machine's spindle and the drill chuck, allowing the chuck to hold various tools like drill bits, reamers, or taps. Key Features: Precision Fit: Engineered with Morse Taper, Jacobs Taper, or Threaded, this arbor provides a seamless connection between your machine's spindle and the drill chuck. High-Quality Construction: Made from premium-grade hardened steel, this arbor is built to withstand rigorous use and maintain its integrity over time. Versatile Application: Ideal for use with [machine types, e.g., drill presses, lathes, milling machines], making it a versatile addition to any workshop. Smooth Operation: Ensures minimal runout, providing you with the precision you need for detailed and accurate drilling or machining tasks. Easy Installation: Simple to attach and remove, allowing for quick tool changes and improved workflow efficiency.

$0.00 - $10.00

-

Tool Steel EN31 Deep Hardened Ultra Precision 1-2-3 Blocks (23 Holes) (1 Pair (2 Pcs))

Made of Quality Alloy Tool Steel Grade EN31 instead of Mild Steel. Read material characteristics of EN31 & its advantages over Mild Steel in description below. Size of the block is 1" x 2" x 3". Total 23 Through Holes being done in 1 operation (5 tapped drills 3/8" x 16 TPI & 18 plain drills) .Drilling & Tapping done on computer controlled Vertical milling center to avoid sloppiness & misalignment. The squareness and parallelism is controlled well within 2-3 microns. Deep Hardened , Matched Pair, Precision Ground , Even Chamferring on all 6 sides. These matched pair can be bolted through any plain hole to the tapped hole to use as a Steps blocks, feelers, Jigs, Angle plate, orientation and setting up tool.

$39.99 $36.99